Food and consumer goods packaging is undergoing significant technological upgrades. On the one hand, the market demands longer food shelf life and reduced reliance on preservatives; on the other hand, sustainable development and regulatory compliance are driving the transformation of packaging materials towards recyclability and biodegradability. In this context, the demand for barrier properties in paper and cardboard packaging has increased significantly, especially in terms of oxygen, grease, and mineral oil barrier properties.

Traditional plastic films (such as PE and PP) have limited oxygen barrier performance, while multi-layer composite materials, although offering excellent performance, increase the difficulty of recycling and compliance. In contrast, water-based barrier coatings can significantly improve the functionality of the material without significantly altering the paper substrate structure, giving paper packaging performance close to that of high-barrier materials while maintaining good recyclability.

Among the many water-based barrier materials, polyvinyl alcohol (PVOH) system coatings have become an important solution for current paper-based packaging barrier technology due to their excellent oxygen and grease barrier properties and mature industrial application base. The KURARAY POVAL (POVAL 6-98), ELVANOL, and EXCEVAL series of products are representative material systems based on PVOH.

1. PVOH Barrier Mechanism and Performance Advantages in Paper Packaging

Polyvinyl alcohol is a non-ionic, water-soluble, linear crystalline polymer, whose molecular chains can form a large number of hydrogen bonds. This highly ordered molecular arrangement makes it difficult for oxygen molecules to diffuse, which is the fundamental reason for its excellent oxygen barrier performance. Under suitable coating and drying conditions, the PVOH coating can form a dense and continuous film layer, thereby significantly reducing the oxygen transmission rate (OTR) of the paper substrate material.

In addition, the hydrophilic nature of PVOH makes it equally outstanding in blocking grease and mineral oil, which is particularly crucial for the packaging of bread, coffee, baked goods, etc. By coating ordinary starch-based paper with EXCEVAL HR-3010, with a coating weight of only 7 g/m², the OTR (Oxygen Transmission Rate) can be reduced from >2000 mL/m²/d to <1 mL/m²/d (23℃, 50% RH), demonstrating extremely high barrier efficiency.

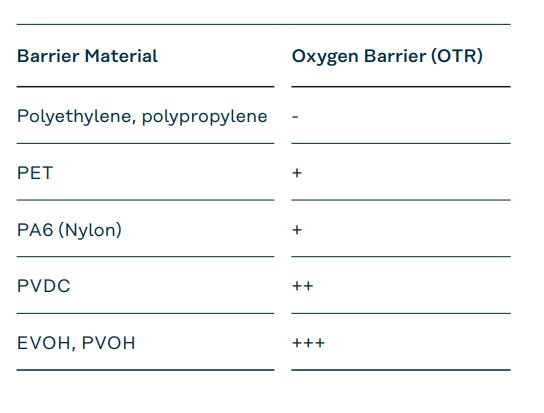

♠ Compared to other common barrier materials, PVOH is a leading material in terms of oxygen barrier performance:

Polyethylene, Polypropylene: Weak barrier

PET, PA6: Medium barrier

PVDC: High barrier but with environmental concerns

EVOH / PVOH: Extremely high oxygen barrier performance

At the same time, PVOH has been certified by BfR and FDA for food contact regulations, making it safe for use in food packaging systems, which is an important prerequisite for its widespread use in the packaging coating field.

2. PVOH Barrier Coating Product System and Typical Performance Parameters

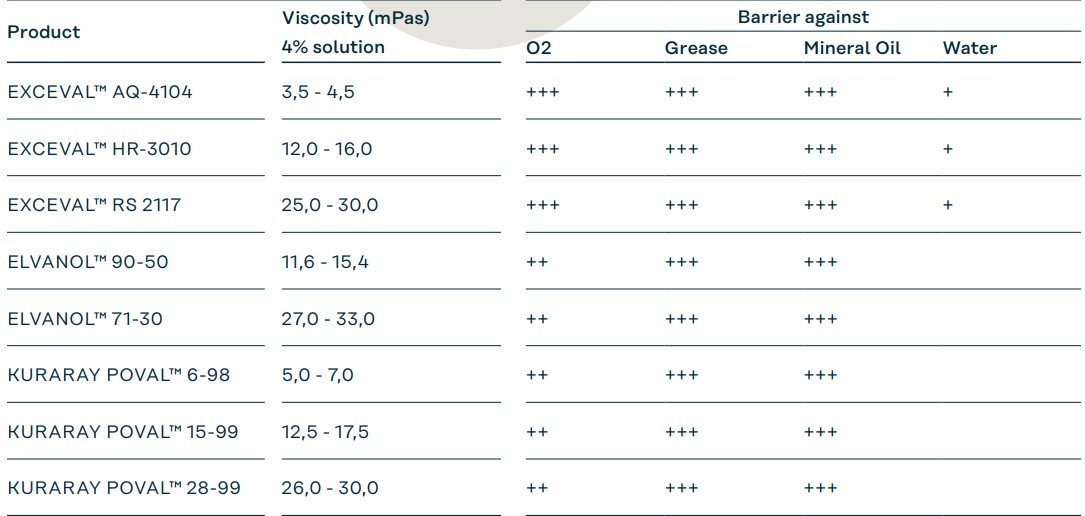

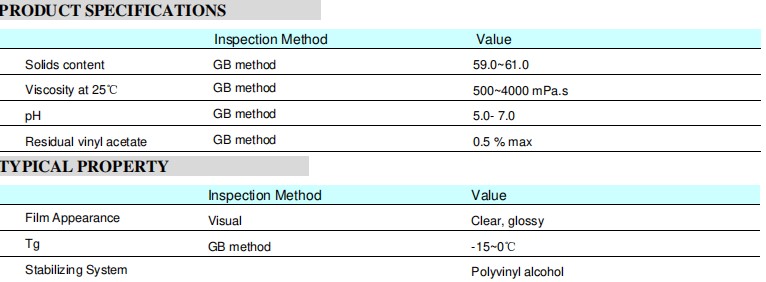

We offer a variety of PVOH product models suitable for paper-based packaging barrier coatings. Different models vary in viscosity, barrier focus, and application suitability, allowing for selection based on actual needs. The following is a performance comparison table:

From an application perspective, low-viscosity models (such as EXCEVAL AQ-4104) are more suitable for high-speed coating or low-coating weight systems, while high-viscosity models (such as ELVANOL 71-30) are beneficial for forming thicker, denser barrier layers. The above products are compatible with various common coating processes, such as blade coating, gravure coating, or curtain coating, and have good process compatibility.

In summary, water-based barrier coatings based on PVOH provide a well-balanced solution for paper-based packaging in terms of performance, sustainability, and regulatory compliance, especially suitable for food packaging scenarios sensitive to oxygen and grease.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

Chloroprene latex is a type of water-based polymer material formed from chloroprene rubber through emulsion polymerization or re-emulsification processes. This series has great adhesion, strong weather resistance, and high flame retardancy, and it can be used in many ways. The series is divided into two main types: anionic chloroprene latex (SNL series) and cationic chloroprene latex (CRL series). These types are based on different ionic properties and can be used in construction, transportation, industrial bonding, surface reinforcement, coating, and impregnation.

1. SNL Series Core Performance and Technological Advantages

♠ Superior Bonding Strength and Initial Tack

In adhesive formulation design, initial tack is a key factor determining production efficiency. SNL series latexes exhibit extremely strong affinity for various substrates, including metals, fabrics, glass fibers, and even porous sponge materials.

♠ Comprehensive Environmental Resistance

Unlike natural latex, which is prone to aging, the SNL series inherits the excellent properties of chloroprene rubber (CR). It possesses excellent resistance to ozone, weathering, oil, and chemical corrosion.

♠ Environmental Protection and Process Adaptability

In today's increasingly stringent environmental regulations, the water-based, non-toxic, and solvent-free characteristics of the SNL series are one of its biggest competitive advantages. It not only eliminates the health and safety hazards caused by volatile organic compounds (VOCs), but also has a "non-irritating" characteristic.

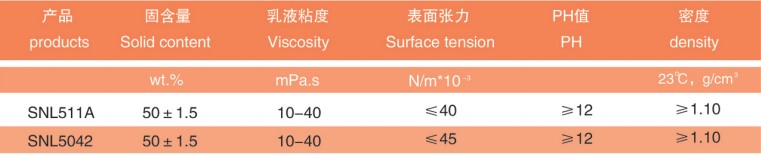

2. Main Model Performance Characteristics and Application Areas

2.1 SNL-511A Anionic Chloroprene Latex

SNL-511A (Neoprene 842A) is a gel-type anionic chloroprene latex with a slower crystallization rate, easy spraying, good flame retardancy, and wide material compatibility. It can be used alone or in combination with natural latex or other synthetic latexes to replace some natural latex applications. Its main application characteristics include:

- Fast-setting spraying application: It can be used in black asphalt waterproof coating systems, suitable for waterproofing and seepage prevention in water plants, pools, sewage tanks, underground foundation treatment, tunnel and subway construction, roofs, balconies, etc.

- Engineering Applications: Waterproof coatings for roads, water conservancy projects, canals, subways, etc.; seepage-proof coatings for reservoirs, underground landfills, etc.; corrosion protection and waterproofing for roof steel structure panels.

- Industrial Applications: Suitable for industrial coatings, impregnated products, composite material adhesives, and can also be used as a bonding substitute for sponge products.

SNL-511A's flame retardancy, sprayability, and wide-range adhesion make it a commonly used variety in engineering waterproofing and industrial protective materials.

2.2 SNL-5042 Anionic Neoprene Latex

SNL-5042 (Denka Neoprene 750) is characterized by strong initial tack, fast bonding speed, high bond strength, good storage stability, no need for solvents, non-toxicity, ozone resistance, oil resistance, chemical corrosion resistance, and excellent flame retardancy. Its main applications include:

- Water-based adhesive systems: Footwear materials, flooring, PVC flooring, foam, mattresses, fiber cloth, aluminum foil, glass cloth, etc.

- Building materials: Bonding of cement, mortar, adhesive mortar, etc., improving the durability and bond strength of the construction site.

- Transportation and Industrial Products: Adhesive materials for industries such as railway vehicles, automobiles, furniture, and electronic components.

This model's fast-drying and strong adhesion characteristics make it particularly suitable for high-efficiency assembly and rapid construction scenarios.

2.3 CRL-50KL Cationic Neoprene Latex

CRL-50KL (Denka Neoprene 571) is a cationic latex with positively charged emulsion particles, thus maintaining stability and preventing aggregation even in environments containing Ca²⁺ and Na⁺. Key features include:

- Excellent weather resistance: Ozone and aging resistant, suitable for long-term exposure environments.

- Good film-forming properties and high strength: Dense and high-strength film, suitable for structural applications such as waterproofing, corrosion protection, and bonding.

- Compatible with various substrates: Strong affinity for materials such as cement, fiber, steel, wood, and fiberglass.

♠ Main applications include:

Modified bitumen waterproofing materials, rigid waterproofing layers, ship deck coatings, etc.

Fiber impregnation, bonding mortars, wood protection, and fiberglass product treatment, etc.

Applications include fire-retardant materials, corrosion-resistant coatings, and structural surface reinforcement.

The salt resistance and high adhesion of cationic systems make them widely applicable in cement, steel, and composite materials.

3. Packaging, Appearance, and Transportation/Storage Requirements

Neoprene latex products are typically white or off-white emulsions. According to available data, the SNL and CRL series products are mostly packaged in 1100 kg ± 2 kg plastic drums for easy transportation and large-scale application.

Transportation and storage requirements include:

- Maintaining a well-ventilated and dry environment during storage and transportation, avoiding direct sunlight and high temperatures.

- Recommended storage temperature: 5–30℃; if the storage temperature is below 23℃, the shelf life of the product is 6 months from the date of production.

- Avoid damaging the packaging and keep it sealed to prevent impurities from entering and affecting stability.

These storage and transportation requirements ensure that the emulsion remains uniform, non-gelling, and non-stratified before use, guaranteeing the safety and consistency of application and processing.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

In the field of specialty rubber materials, chloroprene rubber (CR) has long held an irreplaceable position due to its excellent weather resistance, flame resistance, oil resistance, and chemical corrosion resistance. Among the various types of chloroprene rubber, sulfur-modified chloroprene rubber, with its unique molecular structure design, exhibits excellent physical and mechanical properties and adhesion, making it a key focus in the rubber products industry.

This article will delve into the SN32 and SN12 series of sulfur-modified chloroprene rubber produced using a low-conversion polymerization process. These two series of products, through specific process control, overcome the challenges of Mooney viscosity stability in traditional sulfur-modified rubber, providing a more uniform and reliable raw material choice for industrial products.

1. Characteristics of Sulfur-Modified Process and Advantages of Low-Conversion Polymerization

The core of sulfur-modified chloroprene rubber lies in the introduction of sulfur as a regulator during the polymerization process, and the use of thiuram for chain termination. Compared with traditional thiol-modified rubber, sulfur-modified rubber generally has higher tear strength, better adhesion, and superior dynamic fatigue performance.

The SN32 and SN12 series discussed here are based on a low-conversion emulsion polymerization process. This process is key to improving product quality stability:

- Uniformity of Mooney viscosity: By strictly controlling the monomer conversion rate during polymerization, it effectively avoids polymer gelation or excessively broad molecular weight distribution caused by over-reaction. This means that each batch of rubber produced maintains a very narrow range of Mooney viscosity fluctuations, greatly improving the consistency of compounding and processing in downstream factories.

- Optimization of molecular chain structure: This process, combined with advanced molecular weight regulation technology, results in chloroprene rubber with low crystallinity. Low crystallinity means that the material is softer at room temperature and less prone to premature hardening, thus ensuring the flexibility and service life of the products.

- Improved processing safety: Through precise polymerization control, these two series of products significantly improve the processing safety of the rubber compound while maintaining the high strength of sulfur-modified rubber, reducing the risk of dead stock and scorching.

2. SN32 Series

The SN32 series is positioned as a general-purpose sulfur-modified chloroprene rubber. From a molecular structure perspective, it undergoes a special adjustment of the degree of mechanical shearing and chain scission. According to technical data, the SN32 series has a lower degree of molecular chain mechanical shearing and scission than the SN12 series, but its thermal stability is stronger than the SN12 series. This characteristic determines that SN32 performs better in high-temperature environments.

| Model | SN321 | SN322 | SN323 |

| Mooney Viscosity(100℃1+4) | 37-49 | 50-65 | 66-75 |

| Mooney Scorch (MSt5) min≥ | 25 | 25 | 25 |

| 500% Modulus (Mpa) | 2-5 | 2-5 | 2-5 |

| Tensile Strength (MPa) ≥ | 22 | 22 | 22 |

| Elongation at Break (%) ≥ | 800 | 800 | 800 |

| Volatile Matter (%) ≤ | 1.3 | 1.3 | 1.3 |

| Ash Content % ≤ | 1.0 | 1.0 | 1.0 |

♠ Physical and Mechanical Properties and Processing Characteristics

The SN32 series exhibits excellent physical and mechanical properties, with tensile strength greater than 22 MPa and elongation at break above 800%. Compared with the traditional CR322(such as Polychloroprene Rubber CR3221), the advantages of the SN32 series are mainly reflected in the processing stage:

- Easy to plasticize and compound: The rubber compound absorbs powder quickly and disperses evenly.

- Excellent extrusion molding: The rubber sheet surface is flat and smooth, with low shrinkage, which is crucial for manufacturing extruded products requiring high dimensional accuracy (such as sealing strips and hoses).

- Good appearance quality: The surface of the product is smooth after vulcanization, with a low defect rate.

♠ Grade Subdivision

The SN32 series is subdivided into three main grades according to different Mooney viscosity (ML100℃ 1+4), corresponding to different hardness and processing requirements:

- SN321 (Mooney 37-49): Low viscosity, good fluidity, suitable for complex mold injection molding.

- SN322 (Mooney 50-65): Medium viscosity, most versatile.

- SN323 (Mooney 66-75): High viscosity, higher physical strength, suitable for high-load products.

♠ Key Applications

Thanks to its excellent oil resistance, chemical resistance, ozone aging resistance, and non-flammability, the SN32 series is widely used in mining conveyor belts, power transmission belts, dust covers, and various sealing parts. In particular, its excellent thermal stability makes it perform outstandingly in power transmission components involving frictional heat generation.

3. SN12 Series

♠ Outstanding Scorching Safety and Anti-Aging Properties

The most significant feature of the SN12 series is its long scorching time. In rubber processing, scorch time determines the "safety window" of the operation. A longer scorch time means that the rubber compound is less prone to premature vulcanization (scorch) during high-temperature mixing and molding, which is crucial for thick products or injection molding processes with complex structures. Furthermore, the SN12 series blended rubber exhibits superior vulcanization characteristics, particularly in terms of aging resistance. Data shows that its products have better aging resistance than the GNA type, and also possess good electrical properties and weather resistance.

| Model | SN121 | SN122 | TBD-102 |

| Mooney Viscosity(100℃1+4) | 30-50 | 51-65 | 30-50 |

| Mooney Scorch (MSt5) min≥ | 25 | 25 | 25 |

| 500% Modulus (Mpa) | 2-5 | 2-5 | 2-5 |

| Tensile Strength (MPa) ≥ | 23 | 23 | 23 |

| Elongation at Break (%) ≥ | 850 | 850 | 850 |

| Volatile Matter (%) ≤ | 0.8 | 0.8 | 0.8 |

| Ash Content % ≤ | 1.0 | 1.0 | 1.0 |

♠ Physical Performance Advantages

Although both are sulfur-cured types, the SN12 series has slightly higher tensile strength (≥23 MPa) and elongation at break (≥850%) than the SN32 series. This indicates that the SN12 series has greater molecular chain flexibility and toughness, allowing it to withstand greater deformation without damage.

♠ Differences between SN122 and SN121

The main difference lies in Mooney viscosity; SN122 (51-65) is slightly higher than SN121 (30-50). Users can choose based on the power of their mixing equipment and process requirements.

♠ Comparison with CR121

Compared to traditional CR121(such as Polychloroprene Rubber CR1212), the SN12 series has better processing performance, especially in plasticizing, mixing, and extrusion molding, with less shrinkage and better product appearance quality.

4. Application Scenario Analysis and Series Selection Recommendations

Both the SN32 and SN12 series possess the characteristic "all-round" properties of chloroprene rubber: oil resistance, heat resistance, flame retardancy, and suitability for rubber products with special requirements for comprehensive performance. However, in actual engineering applications, engineers should select materials based on specific needs.

♠ Power Transmission and Mining Fields (Conveyor Belts, Drive Belts)

This is the core application area for sulfur-cured chloroprene rubber. Mining conveyor belts require extremely high flame retardancy and wear resistance, as well as good adhesion between the rubber compound and the reinforcing materials (such as nylon and polyester canvas).

- Recommendation: If thermal stability of the rubber compound is important (e.g., drive belts in high-temperature environments), the SN32 series is the preferred choice.

- Recommendation: If tear strength and a long scorch time are important (facilitating long-term vulcanization molding of large conveyor belts), the SN12 series is more suitable.

♠ Cable Sheathing and Seals

Cable sheathing requires materials with good weather resistance, ozone resistance, and certain electrical insulation properties.

The SN32 series, with its excellent extrusion surface smoothness and low shrinkage, is ideal for extruded cable sheathing and profiled sealing strips, ensuring dimensional accuracy and aesthetic appearance of the finished product.

♠ Hoses and Vibration Damping Products

The high elongation and tensile strength of the SN12 series make it perform exceptionally well in hoses and damping pads subjected to high-pressure deformation. Its excellent dynamic fatigue resistance can effectively extend the service life of damping products.

The SN32 and SN12 series sulfur-modified chloroprene rubber, produced using a low conversion rate polymerization process, represents the advanced level of current domestic synthetic rubber technology. The SN32 series excels in thermal stability and processing appearance, while the SN12 series is known for its scorch safety and high strength and elongation properties. These two series not only meet the standards of comparable high-end international products (such as DuPont, Lanxess, and Denka) in various physical and chemical indicators, but also achieve uniform and stable Mooney viscosity through process innovation, solving a major pain point of processing instability for rubber product manufacturers. They are ideal base materials for manufacturing high-quality rubber products.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

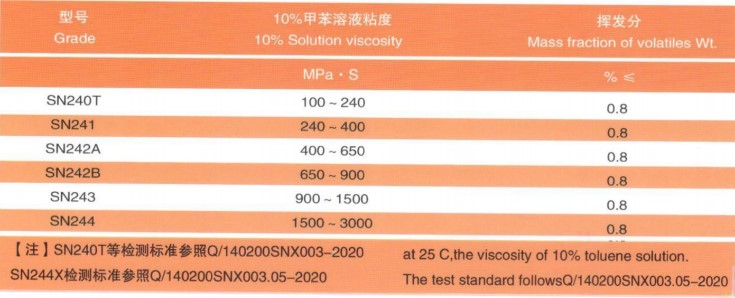

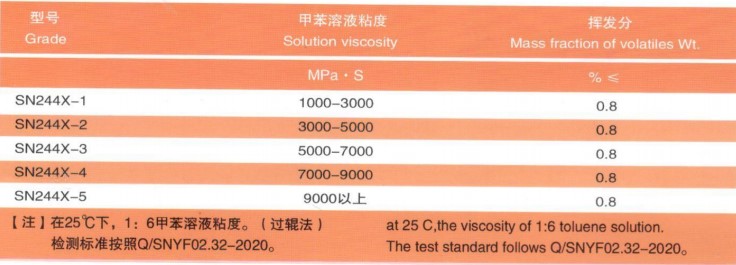

Thiol-modified chloroprene rubber plays a crucial role in adhesive chloroprene rubber systems due to its unique polymerization control mechanism. Thiol-modified products, especially the SN24 series, SN244X series, and SN23 series, are widely used in shoe adhesives, spray adhesives, high-grade universal adhesives, architectural decorative adhesives, and automotive interiors.

1. Mechanism of Thiol Modification

During the polymerization of chloroprene rubber (CR), modifiers significantly affect the polymerization rate, molecular weight, distribution, and controllability of the polymerization process. Thiol modifiers, due to their moderate reactivity, are widely used in the production of adhesive chloroprene rubber.

1.1 More Stable Polymerization Process

Thiol modification effectively controls chain growth, maintaining suitable molecular weight and distribution, resulting in good solubility and stable processing properties. This directly affects adhesive viscosity, film-forming characteristics, and long-term storage stability.

1.2 Determining Initial Tack and Final Strength of Adhesives

Taking the SN24 series as an example, the molecular structure obtained through thiol regulation exhibits superior film-forming strength. When grafted with MMA (methyl methacrylate), it significantly improves adhesion to various substrates, resulting in higher initial tack and final bond strength.

1.3 Affecting Open Time and Working Window

The SN23 series is specifically designed for "adjustable open time." Through meticulous control of the molecular structure, it provides more flexible application times for the footwear and decoration industries, effectively improving operational convenience and production efficiency.

Thiol regulation is not merely simple polymerization control; it is a core technical means influencing the application performance of the entire adhesive system, providing a strong technical foundation for complex bonding scenarios.

2. Performance and Application Value of the SN24/SN244X Series

Among thiol-regulated chloroprene rubbers, the SN24 and SN244X series are the products with the highest market attention. SN24 focuses on bond strength and grafting applications, while SN244X further optimizes solubility, color, and weather resistance, resulting in more comprehensive overall performance.

2.1 SN24 Series: High-strength, graftable, and widely applicable basic products

♠ Key features of the SN24 series include:

Thiol-modified system for stable molecular weight control

MMA grafting adaptability, further improving adhesion to substrates such as metals, leather, and rubber

High initial tack and excellent final bond strength

Suitable for fast bonding systems

♠ Typical applications:

Shoe adhesives in the footwear industry

Spray adhesives in the furniture and packaging industries

Advanced all-purpose adhesives and engineering adhesives

Chloroprene Rubber SN-242A is a widely used product, extensively adopted in footwear adhesive applications due to its strength, fast bonding speed, and ease of use.

2.2 SN244X Series: Upgraded Products with High Solubility, Light Color, and High Weather Resistance

Chloroprene Rubber SN-244X series optimizes several key properties based on SN24, making it a higher-end and more stable thiol-modified chloroprene rubber.

♠ Key advantages include:

Faster dissolving speed, improving production efficiency

Lighter glue color, suitable for light-colored or appearance-sensitive products

High initial bond strength, long holding time, and better weather resistance

Less prone to aging after bonding, suitable for outdoor or strong light environments

♠ Typical applications:

High-end shoe adhesives

Construction and decoration adhesives

Automotive interior bonding

Furniture and decoration industries

For companies requiring "fast dissolution + strong adhesion + high weather resistance," the SN244X series is a typical choice.

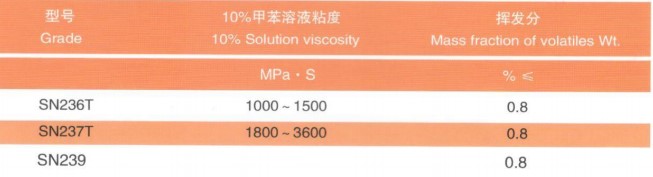

3. SN23 Series: Complementary Products Specifically Designed for Adjusting Open Time

Unlike the direct application of SN24 and SN244X, the SN23 series acts as a "modifier" in adhesive chloroprene systems. Its core value is adjusting the open time.

3.1 Why is open time so critical?

In adhesive applications, too short an open time leads to application difficulties; too long an open time reduces efficiency. Different seasons, application temperatures, and substrate conditions can all cause fluctuations in the final bonding effect.

The SN23 series allows for precise adjustment of the adhesive's drying speed and operating window, ensuring stable performance under various environmental conditions.

3.2 Enhanced results when used in conjunction with SN24/SN244X

The SN23 series is typically not used alone, but rather in combination with SN24 and SN244X, serving the following purposes:

Extending or optimizing adhesive open time

Improving sprayability and application feel

Optimizing the balance between initial and final bond speeds

Enhancing adaptability to complex processes

Typical products such as SN236T and SN237T possess suitable solution viscosity and good stability, making them highly valuable in the footwear and industrial adhesive industries.

As industries such as footwear manufacturing, furniture decoration, and automotive interiors demand increasingly higher performance from adhesives, adhesive-grade neoprene rubber is entering a stage of development focused on higher performance, greater controllability, and greater stability.

♣ The thiol-modified SN24, SN244X, and SN23 series are key components of this trend:

SN24 – High strength, graftable, and comprehensive adhesive properties

SN244X – An upgraded solution offering fast dissolution, light color, and high weather resistance

SN23 – An open-time modifier product that makes production more controllable.

Through proper combination, these adhesives can create more stable, easier-to-process, and more adaptable neoprene adhesive systems, bringing higher efficiency and better bonding quality to end-user industries.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

In the world of cosmetic preservation, formulating at higher pH levels has always been a challenge. Traditional organic acid preservatives like sorbic acid, benzoic acid, or dehydroacetic acid lose their effectiveness as pH rises above 6, leaving formulations vulnerable to microbial growth. This limitation often forces brands to compromise between stability, skin feel, and preservation efficacy.

Enter DropPrev® CHA (Caprylhydroxamic Acid) – a innovative, multifunctional ingredient that breaks the pH barrier.

What is DropPrev® CHA?

DropPrev® CHA is a mild organic acid derived from caprylic acid and hydroxylamine. With the INCI name Caprylhydroxamic Acid and a molecular weight of 159.23, it’s a globally recognized and compliant material, included in China’s IECIC 2015 inventory.

But what truly sets it apart is its exceptionally high pKa of ~9.4.

The pH Game-Changer

For traditional organic acids, antimicrobial activity depends on the percentage of undissociated acid, which drops dramatically as pH increases. At pH 6, an acid needs a pKa of at least 6 to be 50% active. Most conventional preservatives fall short.

DropPrev® CHA defies this trend. Thanks to its high pKa, it remains fully active across a wide pH range.

Comparative Activity at Various pH Levels:

| pH | Dehydroacetic Acid | Benzoic Acid | Sorbic Acid | CHA |

|---|---|---|---|---|

| 3 | 99.5% | 94.1% | 98.3% | 100% |

| 4 | 94.9% | 61.3% | 84.9% | 100% |

| 5 | 65.1% | 13.7% | 36.0% | 100% |

| 6 | 15.7% | 1.6% | 5.3% | 100% |

| 7 | 1.8% | 0.2% | 0.6% | 100% |

This means CHA is the only organic acid that remains completely undissociated and active at neutral pH.

Dual Mode of Action

1. Metal Chelation – Primary Mechanism

-

CHA acts as a potent chelator, particularly for Fe³⁺ (stability constant: 11.4), competing with microbial siderophores for iron.

-

Iron is essential for microbial growth, electron transport, and DNA synthesis. By sequestering iron, CHA starves microbes of this vital nutrient.

-

It also chelates Ca²⁺ and Mg²⁺ at the cell membrane, increasing permeability and disrupting microbial integrity.

2. Classic Organic Acid Activity

-

In its undissociated form, CHA exhibits lipophilic properties, allowing it to penetrate microbial cell membranes.

-

Once inside, it can disrupt internal pH and metabolic processes.

Key Benefits & Features

-

Broad-Spectrum Activity: Effective against bacteria, yeast, and mold. Shown to inhibit Aspergillus niger at a low MIC of 0.078%.

-

Formulation Flexibility: Compatible with emulsions, anhydrous systems, surfactant-based cleansers, and color cosmetics.

-

Similar Log Kow (1.67) to other common preservatives like caprylyl glycol and glyceryl caprylate, indicating favorable skin feel and solubility.

-

High Safety Profile: Widely studied, non-mutagenic (AMES test negative), and historically used as a feed additive.

Recommended Use

-

Usage Level: 0.05% – 0.15%

-

Solubility: Soluble in propylene glycol, glycerin, and surfactants.

-

pH Range: Effective from pH 2–8 (activity gradually decreases above pH 8).

-

Application: Best paired with bacterial and yeast inhibitors (e.g., phenoxyethanol, ethylhexylglycerin, 1,2-octanediol) for broad-spectrum protection.

-

Note: Avoid extended heating above 90°C. Add EDTA-2Na to prevent discoloration from iron-containing clays or minerals.

Conclusion

DropPrev® CHA represents a significant step forward in preservation technology. Its ability to remain active at neutral pH, combined with its dual-action mechanism and strong safety record, makes it an ideal choice for modern, mild, and high-performance cosmetic formulations.

Whether you're developing a gentle facial cream, a pH-balanced shampoo, or a long-wearing makeup product, CHA offers reliable preservation without compromising pH or sensory attributes.

Please contact: judyzhou@drop-bio.com

HVA-2,N,N'-m-phenylene dimaleimide is a multifunctional rubber additive. Besides being widely used in the rubber industry as a vulcanizer, co-vulcanizer, and scorch retarder, it also plays a crucial role in adhesives, primarily due to its ability to significantly improve heat resistance and bond strength.

Certificate of Analysis

|

Product Name |

N,N'-m-phenylenedimaleimide(HA-8) |

|

|

Property |

Limits |

Results |

|

Form |

Free Flowing Powder |

Free Flowing Powder |

|

Color |

Yellow to light Brown |

Yellow |

|

Contamination |

None |

None |

|

Melting Range℃ |

≥195 |

201.8 |

|

Water % |

≤ 0.5 |

0.02 |

|

Ash % |

≤ 0.3 |

0.01 |

|

Oil % |

≤5 |

3.1 |

|

Acidity mgkoH/g |

≤5 |

1.1 |

|

Particle Size On 100 mesh % On 325 mesh % |

0.0Max 0.5Max |

0 0 |

Applications Specific Functions and Effects

Main Function As a heat-resistant modifier (resin monomer), it enhances the overall high-temperature resistance of the adhesive by participating in reactions.

Key Benefits:

1. Significantly Improves Heat Resistance: Enhances adhesive stability in high-temperature environments, preventing failure due to high temperatures.

2. Enhanced Bond Strength: Especially for difficult-to-bond materials such as metals.

Typical Dosage

The recommended addition level in adhesive formulations is generally 5-10 parts.

Applicable Systems For example, Anaerobic Adhesive.

Principle of Action and More Applications

HVA-2 molecules contain active double bonds that can undergo cross-linking reactions under heat or in the presence of an initiator, forming a stable network structure. This is why it can function both as a vulcanizing agent and as a heat-resistant modifier in adhesives.

In addition to its general use as a heat-resistant modifier, search results also mention HVA-2's applications in specific applications:

1.Metal Bonding: When used in high-end hot-melt paints and coatings, HVA-2 can improve adhesion to metals. This property is also suitable for adhesives requiring high-strength metal bonding.

2.Aerospace: Because HVA-2 is an excellent polymer heat-resistant additive, it is also used in heat-resistant materials in the aerospace industry, suggesting its potential application in specialty adhesives requiring extreme heat resistance.

Usage Guidelines and Precautions

When using HVA-2, there are several things to keep in mind:

1.Dosage: In adhesive formulations, the typical dosage is 5-10 parts. The optimal dosage should be determined through specific experiments.

2.Solubility: Understanding its solubility will help you select the appropriate solvent for pretreatment or dilution. HVA-2 is soluble in dioxane, tetrahydrofuran, and hot acetone, but insoluble in petroleum ether, chloroform, benzene, and water.

3.Storage Conditions: This product should be stored in a cool, dry, well-ventilated place, away from light and heat.

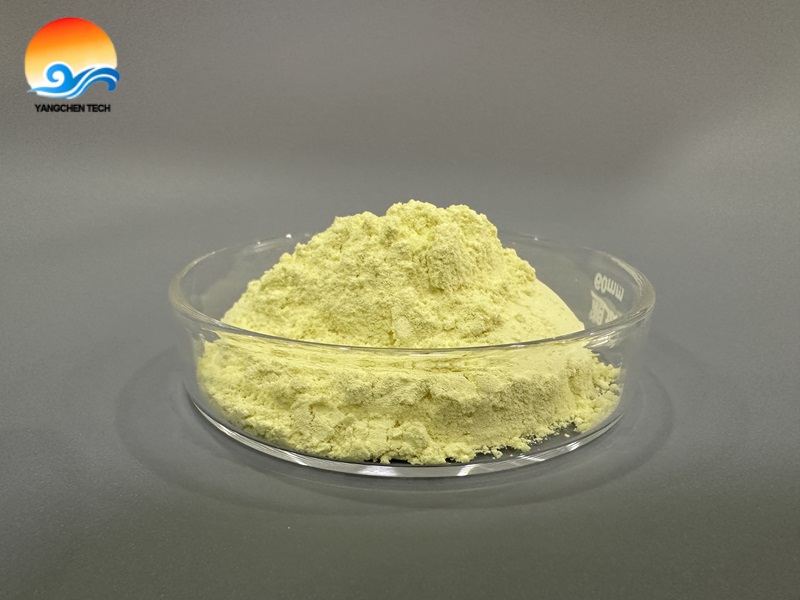

High-Tg Bismaleimide Resin Manufactured By Yangchen Tech

In the high-performance polymers, bismaleimide resin (BMI) stands out for its exceptional thermal stability, mechanical strength, and electrical properties. Yangchen Technology specializes in BMI (CAS: 13676-54-5) with a focus on one key performance metric: glass transition temperature (Tg). Our BMI resins boast Tg values exceeding 340°C, and custom formulations can reach temperatures exceeding 400°C.

Why the Tg of Bismaleimide Resin is Important?

The glass transition temperature (Tg) is the point at which a polymer transitions from a hard solid to a softer, rubbery state. For applications in the aerospace, electronics, and automotive industries, a high Tg ensures:

- Dimensional stability under thermal stress.

- Mechanical properties (e.g., strength, modulus) maintained at elevated temperatures.

- Resistance to deformation during sustained high-temperature operation.

Standard epoxy resins typically have Tg values below 200°C, limiting their use in high-end applications. In contrast, our BMI resins achieve Tg values as high as 400°C through molecular design and compounding. For example, our N,N'-4,4'-diphenylmethane bismaleimide (CAS: 13676-54-5) exhibits a Tg of 340°C after curing for 10 hours at 280°C.

Technical Indicators

| Appearance | Melting point | Acid value |

Volatile |

Specification | Gel time 200℃ | Toluene Solubility |

| Yellow powder | 150-160℃ |

≤1mgKOH/g |

≤1% |

>98% |

<300 S |

Totally soluble or a small amount of insoluble matter, transparent solution |

Key Advantages of Our High-Tg BMI Resins

1. Excellent Thermal Performance

Tg range: 250°C to >400°C, customizable upon request.

Thermal decomposition temperature (Td) as high as 500°C.

Low coefficient of thermal expansion (CTU: 36–40 ppm/°C), minimizing warping and cracking.

2. Enhanced Processability

Low melt viscosity (e.g., 474–51 mPa·s in the 148–180°C range) allows for easy molding, impregnation, or coating.

Wide processing window for composites, adhesives, and encapsulation materials.

3. Excellent Mechanical and Electrical Properties

High storage modulus (e.g., below 3.2 GPa at Tg), ideal for structural components.

Excellent dielectric properties, suitable for electronic insulation.

Practical Applications of High-Tg BMI Resins

Our resins are designed for the following industries, where failure is unacceptable:

Aerospace: Composite matrices for engine components, nose covers, and fuselage structures.

Electronics: Integrated circuit substrates, high-frequency circuit boards, and insulation coatings.

Industrial: High-temperature adhesives, wear-resistant materials, and protective coatings.

Yangchen Technology's Solutions: Tailoring Tg to Your Needs

We understand that different applications have varying Tg requirements. Here's how we provide customized solutions:

1. Formulation Optimization

By adjusting monomer ratios (e.g., DDM-BMI/EBA-BMI blends), we precisely control crosslink density, thereby increasing Tg without compromising processing performance.

2. Cure Optimization Guidance

We provide technical support on curing parameters (time/temperature) to maximize Tg. For example, post-curing at 280°C can increase Tg by 10-15%.

3. Compliance with Industry Standards

Our BMI resins meet stringent thermal stability and safety specifications, ensuring reliability in critical applications.

Bismaleimide series products manufactured by Yangchen Tech

| Product Brand | Product Name | CAS Number |

| BMI-200(Click here) | Phenylmethane maleimide | 67784-74-1 |

| BMI-400(Click here) | Bisphenol A diphenyl ether bismaleimide | 79922-55-7 |

| BMI-500(Click here) | 3,3-dimethyl-5,5-diethyl-4,4-diphenylmethanebismaleimide | 105391-33-1 |

| BMI-600(Click here) | BIS(4-MALEIMIDOPHENYL)SULFONE | 13102-25-5 |

| BMI-800(Click here) | 4-methyl-1,3-phenylenebismaleimide | 6422-83-9 |

Partner with Yangchen Technology for superior BMI resins

At Yangchen Technology, we combine over 20 years of high-performance polymer expertise with a customer-centric approach. Whether you require a BMI resin with a Tg of 300°C or >400°C, we offer:

- Sample testing to verify performance in your application.

- End-to-end support from formulation to manufacturing.

For more details, please visit our website or contact Yangchen Technology's technical team.

Unlocking the highest performance of engineering plastics with advanced thermal stabilization technology

Exploring Heat-Resistant ABS

Acrylonitrile-butadiene-styrene copolymer (ABS) is a widely used engineering plastic, prized for its exceptional toughness, rigidity, and ease of processing. However, standard ABS suffers from a significant limitation: its heat deflection temperature (HDT), typically ranging from 85°C to 95°C, restricting its use in high-temperature applications such as automotive parts, electronic housings, and industrial equipment. To overcome this shortcoming, manufacturers are constantly searching for effective thermal modifiers that balance performance, cost, and processing efficiency. Among these solutions, N-phenylmaleimide (N-PMI) has emerged as a leading additive for thermal enhancement of ABS. This article will explore the science behind N-PMI's effectiveness, aiming to provide high-performance N-PMI solutions for industries worldwide.

1. The Science Behind N-PMI: How It Improves ABS's Heat Resistance

N-PMI is a rigid cyclic monomer with a molecular structure consisting of 1,2-disubstituted vinyl groups embedded in a five-membered ring. When copolymerized with ABS or blended as an additive, it acts as a "molecular scaffold," restricting the mobility of the polymer chains. This restriction raises the glass transition temperature (Tg) of ABS, directly improving its heat resistance without compromising its mechanical integrity. Key mechanisms include:

- Enhanced Chain Rigidity: The phenyl and imide groups in N-PMI introduce steric hindrance, reducing chain rotation and improving thermal stability.

- Synergistic Copolymerization: N-PMI binds to the ABS polymer during the synthesis process, forming covalent bonds that stabilize the matrix and prevent thermal degradation. Research has shown that adding 10% N-PMI to ABS can produce ultra-high-heat-resistant ABS with an HDT of 125-130°C, a 30-40°C improvement over unmodified ABS.

2. Why N-PMI Outperforms Other Thermal Modifiers

While other additives (such as glass fiber, mineral fillers, or other imides) can improve heat resistance, they often sacrifice processability, impact strength, or surface finish. N-PMI offers the following unique advantages:

- Balanced Performance: It simultaneously enhances heat resistance, tensile strength, and melt processing.

- Low-Dosage Efficiency: Even a 1% addition can increase the HDT by 2°C, enabling precise calibration for cost-sensitive applications.

- Compatibility with Additives: N-PMI works synergistically with stabilizers, pigments, and flame retardants, making it an ideal choice for multifunctional composites. In contrast, fillers such as talc or silica can reduce toughness, while other thermal stabilizers typically require higher addition levels, increasing viscosity and complicating processing.

Basic Information

|

Property |

Description |

|

Chemical Name |

N-Phenylmaleimide |

|

Synonyms |

NPMI, Monomaleimide |

|

CAS Number |

941-69-5 |

|

Purity |

≥99% |

|

Appearance |

Pale yellow crystalline powder |

|

Manufacturer |

Shaanxi Yangchen New Material Technology Co., Ltd |

Key Properties of N-Phenylmaleimide

|

Property |

Description |

|

Thermal Stability |

Decomposition temp. >300°C |

|

Glass Transition Temp. (Tg) |

Significantly increases Tg of ABS and other resins |

|

Compatibility |

Compatible with styrenics (e.g. ABS, SAN), epoxy resins, and engineering plastics |

|

Solubility |

Dissolves in acetone, DMF, THF, etc. |

3. Yangchen Technology's Leadership in N-PMI Innovation

As a pioneer in fine chemicals and polymer additives, Yangchen Technology leads the way in N-PMI technology:

A. Advanced Synthesis and Purification Technologies

Yangchen Technology utilizes a proprietary catalytic system and a closed-loop solvent recovery process to produce N-PMI with high purity (>99%) and low coloration. Our approach removes impurities that could accelerate polymer degradation, ensuring optimal performance in ABS formulations.

B. Custom Copolymer Design

We develop customized N-PMI-based copolymers, such as poly(N-phenylmaleimide-styrene-acrylonitrile-α-methylstyrene). These terpolymers exhibit high Tg values of 142.6°C, making them suitable for use as standalone high-temperature resins or as modifiers for ABS/PVC blends.

C. Scalable and Sustainable Production

Our facilities utilize continuous flow reactors and energy-efficient distillation to achieve high yields (≥95%) while minimizing waste. This scalability ensures reliable supply to our global customers, from pilot batches to industrial-scale orders.

4. Practical Applications: Advantages of N-PMI-Enhanced ABS

The thermal stability imparted by Yangchen Technology's N-PMI opens the door to demanding applications in the following industries:

- Automotive: Under-the-hood components, connector housings, and interior trim.

- Electronics: LED housings, power tool housings, and 3D printing consumables.

- Consumer Goods: Kitchen appliances, sanitary ware, and outdoor equipment.

ABS modified with Yangchen Technology's N-PMI retained >90% of its impact strength after 1000 hours at 110°C, >50% higher than conventional ABS.

Any questions,feel free to contact us!

Adjustable Plastic Pedestal: Comprehensive Guide to Features, Applications, Installation & Advantages

Adjustable Plastic Pedestal, commonly known as "Adjustable Base" or "Adjustable Elevated Base" abroad, has been widely used in Europe and America since the 1980s and is now an innovative building product.

Tools/Materials

- Material: High-density polypropylene (PP)

- Core Features: High strength, aging resistance, long service life, strong weather resistance, unaffected by cold, heat, moisture, with a service life of over 25 years.

Application Scenarios

Suitable for wooden terrace construction, flooring installation, landscape engineering, water feature creation, deck docks, garden rooftops, still water surfaces, fountains (jet fountains, dry fountains), anti-corrosion wood installation, grid permeable board overhead, sky gardens, atrium landscapes & terraces, interactive water dance fountains, roof insulation, etc.

Components & Functions

1. Support Head: Fixed on the base or connecting pipe, compatible with keel brackets and various floors, supporting 0-5% slope drainage.

2. Connecting Pipe: Internal and external thread structure for free height adjustment; scale labels ensure safety and stability.

3. Base Plate: Can be positioned/fixed on any substrate, with multiple fixing holes for anchoring screws/bolts, ensuring safety and stability.

4. Spacer Strip: Thickness 2/3.5/5/8/10mm, breakable, adjusts stone gaps (conventional 5mm), facilitates drainage and enhances aesthetics.

5. Gasket: Thickness 1/2mm, cuttable, adjusts uneven stone thickness to ensure flatness and buffers impact between stones and pedestals.

6. Keel Slot: Width 40mm/50mm/60mm/80mm, suitable for different keel needs.

7. Fixing Ring: Reversely locks the pedestal, improves load-bearing capacity, especially effective in sandy environments.

8. Core Advantages: Fully adjustable height, load-bearing over 2 tons, 100% recyclable modified PP material, compatible with marble, granite, wood decks, tiles, drainage grilles, etc.; easy assembly, strong durability, convenient pipeline installation/maintenance, good insulation, no frozen layer issues.

Usage Advantages

- Excellent hiding of pipes and equipment;

- Significantly reduces building load, substantially lowering structural costs;

- Easy leveling and installation;

- Rapid drainage;

- Good thermal insulation;

- Effectively solves water stains and efflorescence;

- Excellent sound insulation;

- Fast installation speed;

- Environmentally friendly;

- Applicable to any floor material;

- Adapts to sudden design changes;

- Construction unaffected by weather;

- Reduces long-term maintenance costs;

- Lowers cleaning, replacement and major renovation expenses;

- Facilitates pipeline configuration and maintenance.

Installation Methods & Notes

1. Installation Method: Install supports corresponding to each floor slab (4 for the first slab, 2 for subsequent slabs) and lay them one by one until complete; Do NOT fix all supports first before laying stone floors (incorrect).

2. Fixing Method: Pour the pedestal base on the ground with cement mortar to avoid damaging the waterproof layer.

3. Installation Notes: ① The pedestal bears load via threads; ensure at least 3-4 threads engage when adjusting height, avoiding uneven tightness; ② After adjusting height, tighten the green fixing ring downward in the reverse direction to prevent wobbling.

In the dry-mix mortar industry, the performance of redispersible polymer powder (RDP) directly determines the bonding strength and flexibility of tile adhesives, exterior wall putties, and thermal insulation mortars. As the source of RDP production, the physicochemical properties of VAE emulsions form the cornerstone of all these properties. Today, we will delve into two specialized VAE emulsions designed specifically for RDP production—DiverSol 628 (VAE CW40-758) and DiverSol 688 (VAE CW40-718).

1. Balance between High Solids Content and Rheological Properties

For RDP (polymer powder) manufacturers, spray drying is the most energy-intensive process. The solids content of the emulsion raw materials directly affects production efficiency and energy costs. DiverSol 628 and DiverSol 688 demonstrate extremely high industrial economics in this regard.

In the VAE emulsion field, a solids content of around 60% is considered high. This means that the amount of water that needs to be evaporated during the spray drying process is significantly reduced. Compared to conventional 55% solids content emulsions, using the DiverSol series not only significantly reduces heat consumption but also substantially increases the unit output of spray towers.

Besides solids content, viscosity is crucial for atomization performance. DiverSol 628/688 have a viscosity range of 500 ~ 4000 mPa·s (25℃). This wide viscosity range, combined with its excellent flow properties, provides powder manufacturers with a wide process window:

- Good atomization: Appropriately low viscosity helps the emulsion form tiny droplets at the nozzle, resulting in more uniform particle size distribution in the dried powder, and better flowability after blending.

- Shear stability: Under high-speed pumping and spray shearing, the emulsion remains stable and is less prone to emulsion breakage and nozzle clogging.

Furthermore, both products use polyvinyl alcohol (PVA) as a protective colloid system. This system is standard in RDP production because polyvinyl alcohol not only stabilizes the emulsion but also acts as a protective film during the redispersibility of the adhesive powder, preventing the powder particles from clumping in water and ensuring rapid dispersion of the final dry mortar after water addition.

2. Differentiated Formulation Strategy Based on Tg Value

Although DiverSol 628 and 688 are highly consistent in their basic physical properties (appearance, solid content, viscosity, pH), they take two completely different technical directions in their core thermal performance indicator—glass transition temperature (Tg), targeting "rigid" and "flexible" applications respectively.

2.1 DiverSol 628: High Tg Leads to Rigidity and High Strength

♣ Tg Range: 10 ~ 20°C

♣ Technical Characteristics: A Tg higher than room temperature means that the movement of polymer molecular chains is restricted after film formation, resulting in a film with higher hardness and cohesiveness.

♣ Application Advantages: RDP produced using 628 is more suitable for applications requiring high bond strength and surface hardness. For example:

- Tile adhesive: Provides strong tensile strength, preventing heavy tiles from slipping.

- Floor mortar and self-leveling compound: High Tg helps improve the abrasion resistance and hardness of the floor surface.

- Gypsum-based applications: Enhances the strength of gypsum products.

2.2 DiverSol 688: Low Tg provides flexibility and crack resistance.

♣ Tg range: -15 ~ 0℃

♣ Technical characteristics: Significantly lower Tg than room temperature, the film is in a highly elastic state after formation, the film is soft, and has excellent elongation.

♣ Application advantages: RDP produced using 688 has its core selling points in flexibility and weather resistance. It effectively absorbs the deformation stress of the substrate, suitable for:

- External wall insulation systems: Prevents cracking of the insulation layer in environments with large temperature variations.

- Flexible putty: Provides excellent crack resistance, adapting to minor vibrations or settlement of the wall.

- Repair mortar: Provides necessary bridging ability when repairing old and cracked substrates.

3. Industrial Compatibility and Green Environmental Protection

In actual industrial production, VAE emulsions not only need excellent performance but also must possess good "compatibility," meaning they must be compatible with other raw materials.

3.1 Broad Chemical Compatibility

DiverSol 628/688 were formulated with the complexity of downstream applications in mind. These two emulsions typically exhibit good compatibility with various thickeners, plasticizers, solvents, and fillers. This is crucial for RDP manufacturers, as anti-caking agents or other modifying agents are often added to the emulsion before spray drying. Good compatibility ensures the homogeneity of the mixture, preventing stratification or flocculation.

3.2 Environmental Protection and Aging Resistance

With increasingly stringent GB standards for the environmental protection of building materials, the environmental properties of raw materials have become a critical indicator.

- Plasticizer-Free Design: Both products are formulated without plasticizers. This means that the film-forming flexibility of the emulsion comes from the internal plasticizing effect of the ethylene monomer, rather than from added small-molecule plasticizers. This not only prevents later-stage brittleness caused by plasticizer migration but also ensures excellent aging resistance.

- Low Residual Monomer: The residual vinyl acetate monomer content is strictly controlled below 0.5%, making it an environmentally friendly product.

3.3 Storage and Handling Guidelines

While the product boasts excellent performance, proper handling is equally important. Due to the presence of trace monomers, it is recommended to handle the product in a well-ventilated environment and wear protective equipment. Storage temperature should be controlled between 5°C and 40°C; freezing is strictly prohibited. It is particularly important to note that if the product has undergone long-distance transportation or long-term storage (shelf life 6 months), it is recommended to filter and stir before use to eliminate any potential lumps or crusts.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

- Bismaleimide Series2

- Cross-Linking agent / Vulcanizing Agent1

- Curing Agent1

- Engineering Plastic Pellets4

- Epoxy Resin2

- Ethylene-VinylAlcohol Copolymer(EVOH)1

- Fish Oil1

- Food Additives3

- Glucosamine1

- Heat-resistant modifier series1

- High Assay Quaternary Ammonium Compounds9

- Low Assay Quaternary Ammonium Compounds13

- Modified Polyvinyl Alcohol1

- Monomalemide Series2

- Other Surfactants/Catalysts8

- Plastic Random Packing1

- Plastic Structured Packing1

- Polyacrylamide1

- Polyurethane Resin2

- Polyvinyl Alcohol (PVA)2

- Power Coatings3

- Quaternary Ammonium Hydroxide4

- Special Quaternary Ammonium Compounds7

- TPU4

- Tertiary Amines1

- UV Ink1

- VAE Emulsion (Vinyl Acetate–ethylene Copolymer Emulsion)1

- aluminum paste1

- antiform2

- fire sleeve2

- resin2