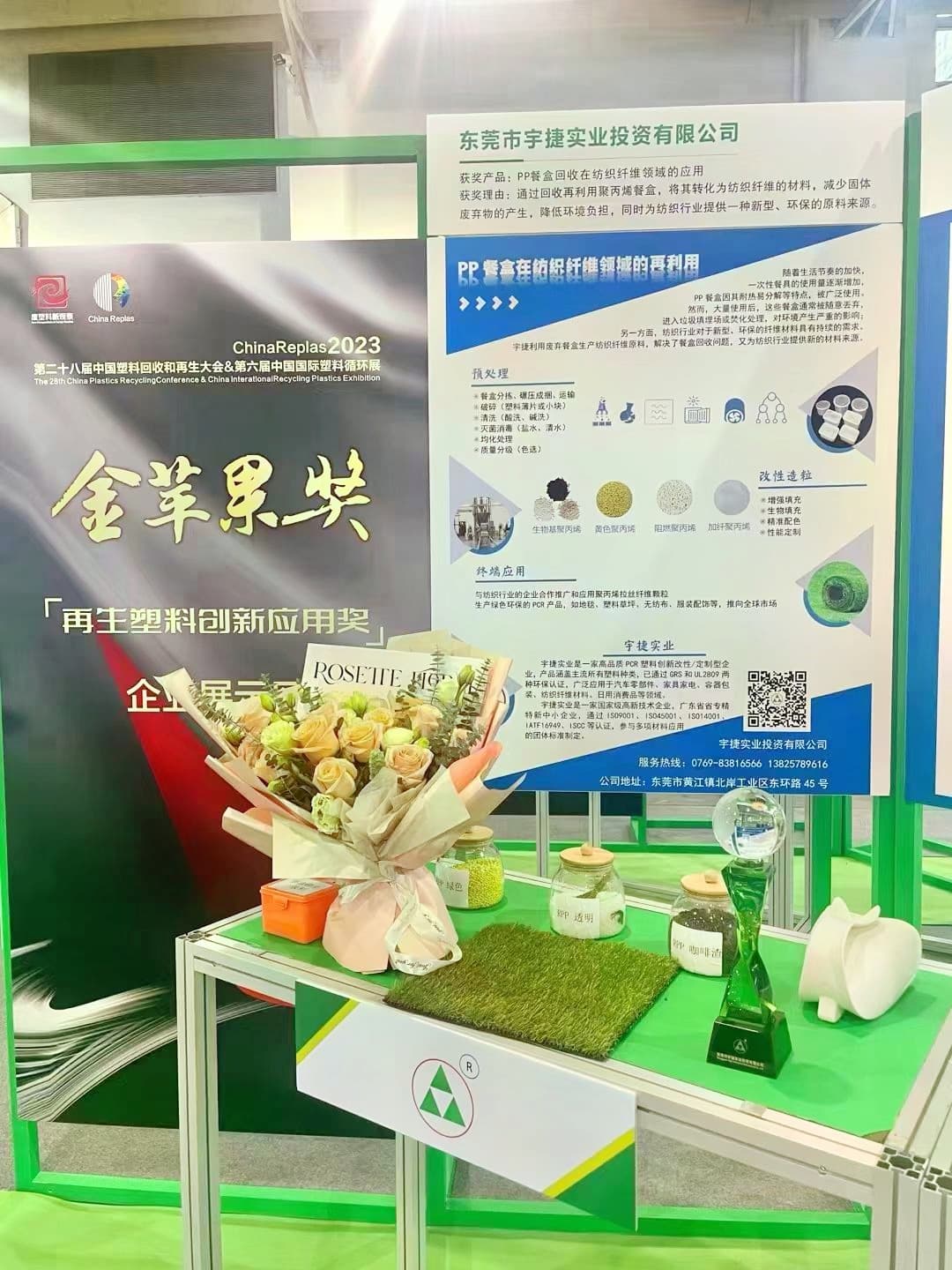

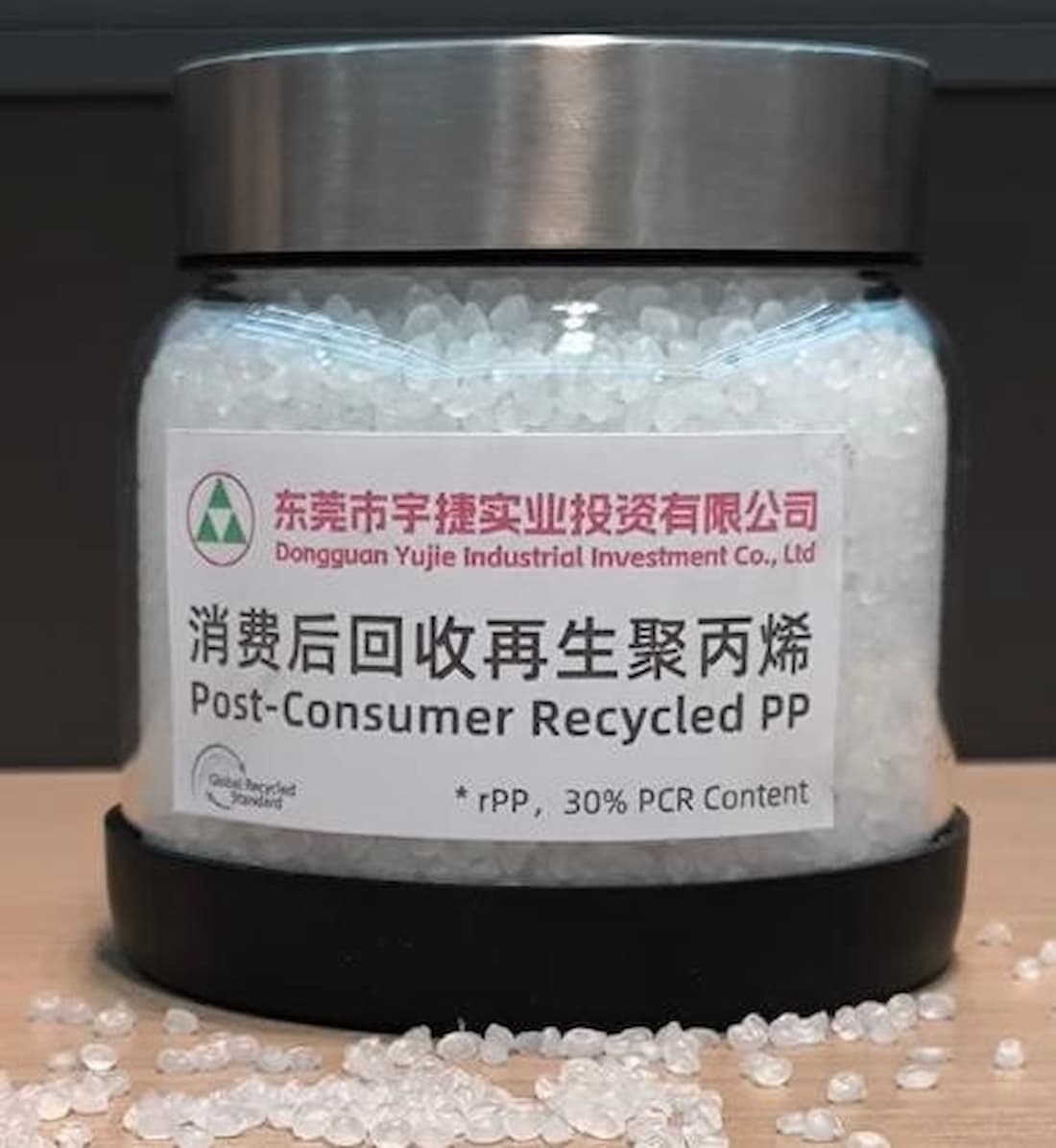

Yujie Industrial recycling of discarded takeout containers, resulting in the modification and application of Recycled PP pellets (PCR-PP Post consumer recycled PP granules) , a key plastic raw material.

The Recycling Journey of Takeout Containers: From White Pollution to Recycled Polypropylene Granules Comparable to Raw Materials.

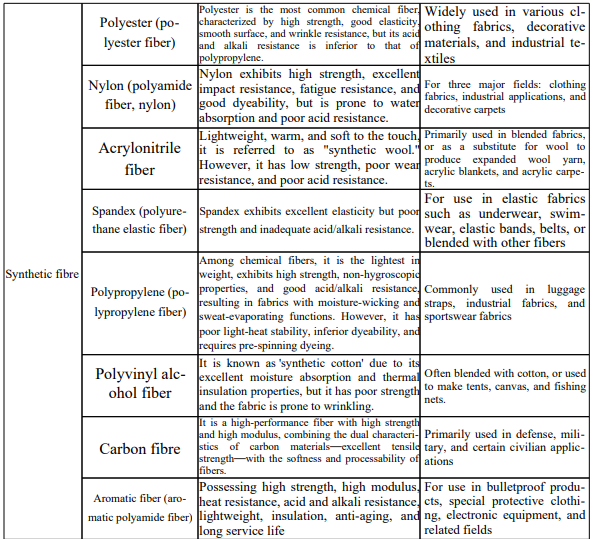

Polypropylene can be classified into five categories according to processing requirements:

Film Grade, Injection Grade, Pipe Grade, Fiber Grade, and Yarn Grade. In PCR-PP applications, the first three are well-established, with relatively standardized processes and widespread application, resulting in high familiarity. The latter two are used only in specific scenarios and fields, requiring different processing techniques for different products.

I. Fiber Grade PCR-PP(Post consumer recycled PP pellets): Polypropylene fiber, also known as polypropylene fiber, comes in long fiber, short fiber, spunbond nonwoven fabric, meltblown nonwoven fabric, and other types. Compared to other fibers, polypropylene fiber possesses the lightest, warmest, and most hydrophobic properties. Its fiber density is only 0.91 g/cm³, the lowest among the five major synthetic fibers, and approximately 34% lighter than polyester fiber. Polypropylene fiber has a thermal insulation rate of 36.49%, the highest among the five major synthetic fibers, 1.7 times that of polyester. Its standard moisture regain is almost zero, exhibiting the best hydrophobic and moisture-wicking properties. Simultaneously, polypropylene fiber has good acid and alkali resistance and heat aging resistance. With appropriate modification, it can produce high-performance weather-resistant, heat-resistant, and acid and alkali-resistant polypropylene fibers, widely used in concrete, geotextiles, sanitary materials, sportswear, and carpets.

Long fibers can be divided into ordinary long fibers and fine denier long fibers. Fine denier polypropylene fibers, with a fineness ≤2.2 dtex, possess good luster, soft hand feel, excellent drape, and low density, making them suitable for the knitting industry. They can be interwoven with cotton, viscose, silk, spandex, etc., to create cotton-covered polypropylene and silk-covered polypropylene products, ideal materials for high-end sportswear and T-shirts.

They can also be used to produce bulked continuous filament (BCF), with wide applications in decoration and clothing.Currently, 90% of global carpet backing and 25% of carpet yarn are made from polypropylene fibers.

The resulting fine denier polypropylene fibers have a good hand feel, soft texture, and gentle luster; their wicking effect gives them moisture-wicking properties.

The production process for short fibers mostly employs porous, low-speed, continuous processes, i.e., short-fiber spinning. Polypropylene short fibers blended with cotton can be used to make polypropylene-cotton fabrics and sheets; blended fibers with viscose can be used to make blankets; and pure polypropylene and blended yarns are also available. The fiber thickness for hygiene products is 1.5-2.5 dtex, while the fiber thickness for ground fabrics is 5-10 dtex.

Spunbond nonwoven fabric, also known as filament nonwoven fabric, is made by extruding, spinning, stretching, web-laying, and bonding polypropylene raw materials. It features a short process, low cost, high productivity, excellent product performance, and wide range of applications. Polypropylene nonwoven fabric is widely used in various fields of production and daily life (such as disposable medical and hygiene products, disposable protective clothing, agricultural fabrics, furniture fabrics, and shoe linings).

Meltblown nonwoven fabric technology produces very fine fibers (down to 0.25 μm). Meltblown fabric has a large specific surface area, small pores, and high porosity, thus its filtration, shielding, and oil absorption properties are difficult to achieve with nonwoven fabrics produced by other individual processes. Meltblown nonwoven fabric is widely used in medical and hygiene products, thermal insulation materials, and filter materials. Meltblown fabric is "blown" out, using a high-speed stream of hot air to stretch the polymer melt extruded from the spinneret, forming ultrafine fibers that are collected on a wire mesh or roller and bonded together. Therefore, the polypropylene used in medical and hygiene products is mainly high melt index polypropylene fiber.

In addition, polypropylene fibers are also well-suited for producing home carpets. Pile carpets are generally made from low-twist polypropylene fibers. These carpets offer properties such as heat insulation, insect resistance, easy washing, low shrinkage, and lightweight, making them ideal for home use.

Artificial turf is another application of polypropylene fibers. A plastic lawn or a pile artificial turf (called chemical grass) is made by looping polypropylene flat filaments. These artificial turfs are used in stadiums along highways, central squares, transportation hubs, and other scenic areas. Polypropylene fibers have relatively low sun resistance, so UV absorbers are added during manufacturing.

II. Filament-Grade PCR-PP(Post consumer recycled PP pellets)

Generally speaking, filament-grade RPP is mainly used in the plastic weaving industry. It is corrosion-resistant, non-absorbent, and has excellent tensile strength, making it particularly suitable for packaging bags such as FIBCs, woven bags, and heavy industrial cement bags.

Filament-grade HDPE is used for cables, nets, etc., while yarn-grade PP is used for fabric ropes, woven bags, (for sunshade or covering) tarpaulins, carpet backing (base fabric), FIBCs, tarpaulins, and rope production. These products are mainly used for packaging grains, fertilizers, cement, sugar, salt, industrial materials, and minerals.

Filament-grade PP is a major raw material for woven products. Because its processing technology is the easiest to control, most new plants produce filament-grade PP during commissioning. Its production processes mainly include liquid-phase bulk method, gas-phase method, and a combination of liquid-phase bulk and gas-phase methods. The properties and structure of PP filament-grade PP produced by different processes also vary. The melt flow index (MFI) of fiber-grade PP has a reference range of 2.5-3.5 g/10 min. Besides its application in woven product manufacturing, it can also be used to produce thick and glossy BOPP films, and can be blended with injection molding materials to produce injection molded products.

Thank you for reading!Thank you for your support!

Yujie Industrial website : www.yujiepcr.com Email: 13030895350@163.com

Please feel free to contact us : William Chen Whatsapp/Wechat: +86 13030895350

If this article was helpful, please forward and share it.

Follow us to learn more about plastics, master green information.

Share low-carbon and environmentally friendly concepts to make our lives healthier!

Yujie Industry has always put its business philosophy of "Quality, Responsibility, Innovation, and Sharing" into practice, adhering to the social belief of "Win-Win Cooperation and Eternal Integrity," and is committed to becoming a socially responsible and trustworthy high-quality enterprise.

Technical seminar on the national standard "Data Collection and Usage Specifications for Trustworthy Traceability System of Recycled Materials" was held in Beijing today.

A national standard technical seminar on the "Data Collection and Usage Specifications for a Trustworthy Traceability System for Recycled Materials" was held in Beijing on January 29, 2026.

The seminar aimed to discuss the core technical aspects of the standard, promote the standardization of data collection and use for recycled material traceability, and support the development of the circular economy.

Key Points of the Seminar

- Organization Background: Organized by the Digitalization Working Group of the National Plastics Standardization Technical Committee and other organizations, the seminar focused on data standardization issues related to the entire recycled material traceability chain.

- Core Topics: Discussion of key aspects including the standard framework, data collection scope, data format, usage rules, security and privacy protection, and adaptation to traceability technologies (such as blockchain and digital tags).

- Participants: Representatives from enterprises, research institutions, testing and certification bodies, and industry associations across the recycled materials industry chain were present to contribute suggestions for improving the standard.

- Significance: The seminar helps address the industry pain points of "unclear origin and uncontrollable destination" of recycled materials, provides technical support for enterprise compliance and market acceptance, and promotes the application of recycled materials and the construction of a green supply chain.

Overseas customers stock up on goods before the Chinese New Year.We are going to export 25 containers of PCR plastic materials within a week!

Yujiepcr modified plastics materials has been successfully exported to more than ten countries and regions.

Yujiepcr plastic are widely used in products such as non - woven fabrics, auto parts, and electrical appliance casings.

Yujie industrial serve many world-renowned brands, such as IKEA, Walmart, TTI, Yao Ming Ribbon, and Deli Stationery...

Best regards,

We can modified and customized for you .

Please feel free to contact us. Thank you !

Yujiepcr website: www.yujiepcr.com

William Chen Whatsapp/Wechat: +8613030895350 Email:13030895350@163.com

Bio-based materials are materials prepared from renewable biomass (plants, microorganisms, waste oils, etc.) through bioconversion, chemical synthesis, or physical processing.

Bio-based products are wholly or partly derived from materials of biological origin (such as plants, animals, enzymes, and microorganisms, including bacteria, fungi and yeast).

Their core characteristics are low carbon, renewability, and partial biodegradability.

They are used to replace petroleum-based materials, aligning with "dual carbon" (carbon dioxide, oil, and gas) and green supply chains.

I. Core Concepts and Common Confusions

- Bio-based ≠ Biodegradable: Bio-based depends on the source of the raw materials (renewable); biodegradable depends on whether it is decomposed by microorganisms after disposal (e.g., PLA requires industrial composting, while PHA can degrade naturally).

- Ideal type: Such as PLA and PHA, combining bio-based and biodegradable properties, achieving a closed-loop carbon cycle.

- Key indicators: Bio-based content (%), carbon footprint, low-carbon certifications such as ISCC/GRS, and performance matching (compared to petrochemical-based materials).

II. Mainstream Categories and Characteristics

Category | Raw Material | Performance | Typical Application

PLA (Polylactic Acid) | Corn/Sugarcane | Transparent, good rigidity, heat resistant to approximately 60℃ | Packaging, tableware, 3D printing

PHA (Polyhydroxyalkanoate) | Microbial fermentation | Naturally degradable, biocompatible | Medical consumables, food contact

Bio-based PP/PE | Waste oil/Starch | Consistent with petrochemical-based properties, low carbon | Automotive interiors, packaging films

Bio-based PA | Castor oil/Bio-based dicarboxylic acid | High strength, wear-resistant | Automotive parts, electronic casings

Starch-based Plastics | Starch + Biodegradable polyester | Low cost, biodegradable | Disposable daily necessities

III. Core Process Paths

1. Bioconversion: Fermentation/Enzyme catalysis (e.g., starch → lactic acid → PLA, microbial synthesis of PHA).

2. Chemical Synthesis: Biomass → Platform compound (ethanol/succinic acid) → Polymerization (e.g., bio-based PE).

3. Physical Modification: Blending/Filling (e.g., starch + PLA to improve toughness and reduce cost).

IV. Market and Competition (2025 projections)

- Scale: Global bio-based plastics production is approximately 12 million tons, with China accounting for approximately 4 million tons; Bio-PP/Bio-PE accounts for approximately 30% (global ≈ 3.6 million tons, China ≈ 1.2 million tons).

- Market Structure: First tier (Borealis, BASF, etc., single-plant capacity > 300,000 tons); Second tier (Yujie, Jindan, etc., 50,000-100,000 tons); Third tier (small and medium-sized manufacturers < 50,000 tons).

- Trends: Non-grain-based (waste oil/straw), performance-enhancing modification, cost reduction (economies of scale).

V. Application Scenarios and Customer Demands

- Packaging: Food/daily chemicals/express delivery, emphasizing low-carbon compliance, biodegradability, transparency, and airtightness.

- Automotive: Interior trim/lightweight components, requiring IATF 16949 compliance, low VOCs, and a 15%-30% reduction in carbon emissions.

- Medical: Syringes/sutures, requiring medical-grade, biocompatible, and absorbable materials.

- Home Furnishings/Electronics: Casings/accessories require UL/environmental certification, weather resistance/scratch resistance modifications.

- Core Requirements: Low-carbon compliance, performance standards met, stable supply, and traceable carbon footprint.

VI. Industry Challenges and Opportunities

- Challenges: Higher costs than petrochemical-based products (10%-50% premium); performance shortcomings in some categories (e.g., low heat resistance of PLA); unstable scale and raw material supply.

- Opportunities: Driven by EU CBAM and China's dual-carbon policies; mandatory green procurement by brands; cost reduction and efficiency improvement through non-grain technology breakthroughs.

VII. Yujie Industrial has the Differentiated Path

- Non-grain waste oil (gutter oil/waste palm oil) route, with a significant carbon footprint advantage.

- Bio-based + PCR composite, complete ISCC、GRS、OBP certifications, providing CBAM compliance data.

- Modification technologies (fiber reinforcement/fire retardancy/toughening), performance comparable to petrochemical-based products, suitable for multiple scenarios.

Yujie Industrial has the non-grain waste oil raw material has a unique pathway, complete ISCC certification, modification capabilities that meet the high-end needs of automobiles and packaging, and a carbon footprint advantage that aligns with "dual carbon" and the EU CBAM. It forms a green matrix with PCR/OBP and is associated with brands such as IKEA.

Thank you for reading.

Best regards,

We can modified and customized for you .

Please feel free to contact us. Thank you !

William Chen Whatsapp/Wechat: +8613030895350 Email:13030895350@163.com

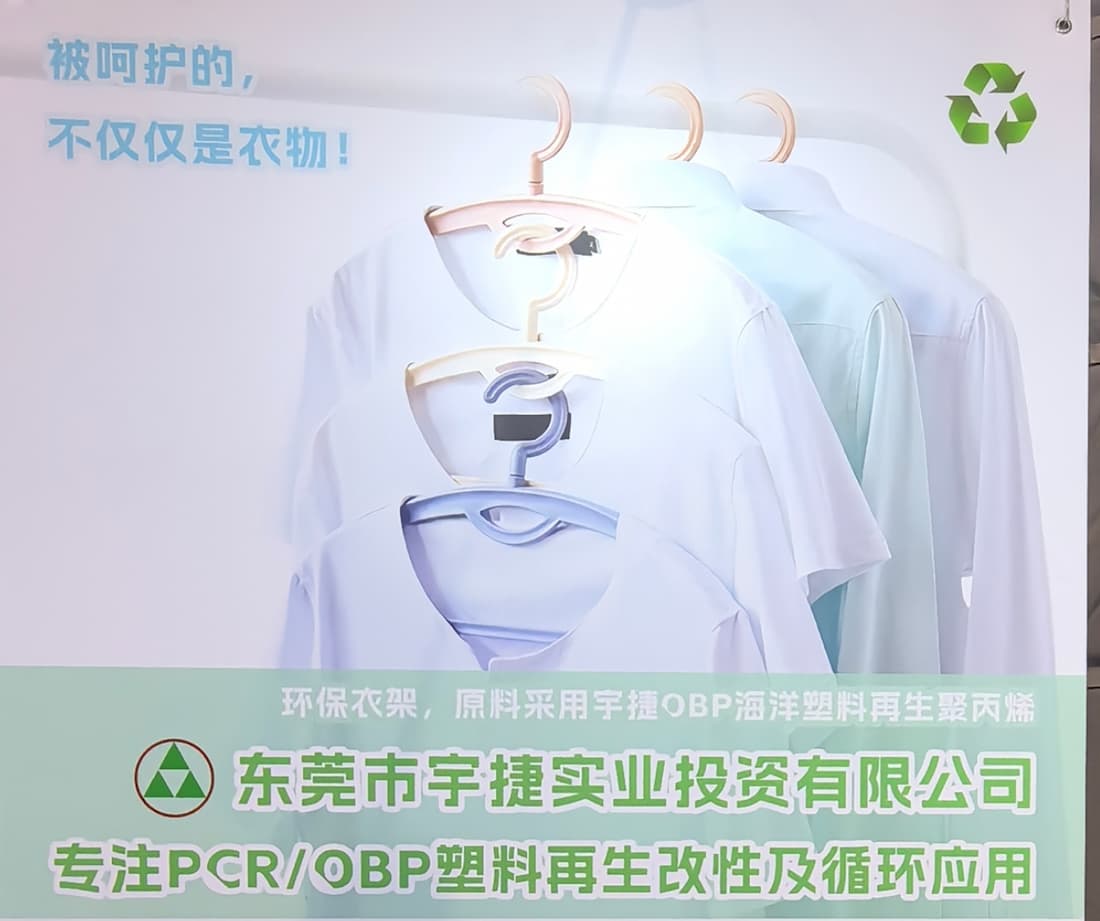

OBP (Ocean Bound Plastic) refers to environmentally friendly raw materials made from recycled plastic waste within 50 kilometers of the coastline that has not entered the sea. The core categories are OBP-PE/PP/PET/PA/PC/ABS, emphasizing low carbon footprint and traceability.

Marine plastic debris (OBP) refers to plastic waste that "poses an eventual loss to the ocean." It is estimated that marine plastic debris accounts for 80% of all marine plastic waste. It includes:

A small portion of commercially recyclable plastic waste

A large portion of non-commercially recyclable plastic waste

I. Core Definition and Classification

- Definition: Recycled plastic waste from within 50 kilometers of the coastline (including beaches, estuaries, and near-shore fisheries), processed through sorting, washing, and modification into recycled granules, can replace virgin materials and significantly reduce carbon emissions.

- Classification

- Potential OBP: Within 50 kilometers of land, not entering the sea

- Collected OBP: Recycled from beaches/coastal zones

- Fishing Activity OBP: Fishing nets/gear and other fishery plastics

- Clarification: Do not confuse with "benzoyl polyester OBP" (polystyrene), the former is a recycled environmentally friendly material, while the latter is a specialty engineering plastic.

II. Key Characteristics and Performance

- Environmental Attributes: Reduces marine plastic pollution by approximately 1.2 tons per ton; carbon emissions are reduced by 50-70% compared to virgin materials; supports GRS/OBP/ISCC full-chain certification and TC trading license.

- Basic Properties (taking OBP-PE as an example): Melt flow index 1.5-3.0 g/10min, tensile strength ≥25 MPa, impact strength ≥12 kJ/m², flexural modulus 800-1000 MPa, close to virgin material levels.

- Modification Directions: Reinforcement, toughening, heat resistance, antibacterial properties; suitable for injection molding/blow molding/extrusion processes.

III. Mainstream Categories and Applications

Category | Core Source | Typical Application

OBP-PE (HDPE/LDPE) | Plastic Bottles/Films/Drums | Packaging Containers, Outdoor Furniture, Marine Engineering Accessories

OBP-PET | Beverage Bottles/Packaging | Cosmetic Packaging Materials, Textile Fibers, Sheets

OBP-PP | Turnover Boxes/Daily Necessities | Injection Molded Parts, Automotive Interiors, Home Appliance Housings

OBP-PA | Fishing Nets/Ropes | Textile Fibers, Engineering Components, Cable Ties

OBP-PC/ABS | Electrical Appliance Housings/Automotive Parts | Electronic Housings, Medical Accessories, Automotive Interiors

IV. Certification and Traceability Key Points

- OBP Certification: International standard, including recycling location, proportion, and traceability; requires a TC transaction certificate.

- Supporting Certifications: GRS/ISCC/UL, covering recycled components, social responsibility, and carbon footprint; essential for export.

- Traceability Requirements: Each batch must be accompanied by proof of recycling origin + TC certificate + test report to meet brand compliance requirements.

V. Production Process and Manufacturers

- Process: Recycling → Sorting → Cleaning → Crushing → Granulation → Modification → Testing → Certification → Shipment. - Major Domestic Manufacturers

Yujie Industrial is a leading specialized and innovative enterprise in the field of PCR modification in China, with outstanding advantages in customization, full-category coverage, international certification, and localized services.

- Yujie Industrial: Full range of OBP-PE/PP/PET/PC/ABS products, GRS、OBP、ISCC certified, annual production exceeding 50,000 tons, suitable for packaging、automotive、electronics. All materials are available to support customized production.

VI. Selection and Procurement Recommendations

1. Select product category by application:

OBP-PE/PET for packaging, OBP-PP/ABS for structural components, OBP-PA for textiles.

2. Required documents: OBP certification, GRS/ISCC certificate, TC certificate, batch test report.

3. Performance matching: Melt flow index, impact/tensile strength, and weather resistance must meet product requirements.

4. Delivery and MOQ: Standard MOQ is 25kg, negotiable for bulk orders; urgent orders require advance scheduling.

Best regards,

We can modified and customized for you .

Please feel free to contact us. Thank you !

Cooperation Consulting contact Person: William Chen

Tel: +86 13030895350

Email: 13030895350@163.com

Yujiepcr website: www.yujiepcr.com

PCR plastic short for Post-Consumer Recycled Plastic, refer to plastic materials made from recycled consumer plastic waste through processes such as sorting, washing, crushing, and granulation. This effectively reduces plastic pollution and the use of virgin plastics.

- Core Advantages: Strong environmental attributes, reducing carbon footprint and petroleum resource consumption; some modified PCR materials have performance close to virgin materials, offering better cost-effectiveness; aligns with global trends of "plastic reduction" and "carbon neutrality," meeting the sustainable development needs of brands.

- Common Categories: Mainstream types include PCR PP, PCR PE, PCR PET, PCR ABS, and PCR PC, suitable for various processing techniques such as injection molding, blow molding, and extrusion.

- Key Indicators: The core dimensions for measuring quality are the percentage of recycled content (requires third-party certification), mechanical properties (tensile strength, impact strength, etc.), hygiene and safety (complies with FDA, LFGB, and other food contact standards), and appearance (color, impurity content).

-Application limitations: The weather resistance and heat resistance of ordinary PCR materials are slightly inferior to those of virgin materials, and batch stability is easily affected by recycled raw materials; high-requirement fields (such as precision electronics and medical consumables) need to improve performance through deep modification or composite processes.

The global PCR (post-consumer recycled plastics) materials market size varies slightly depending on the statistical method used. Key figures are as follows (as of the end of 2025, in USD):

- 2024: Approximately US$36.96 billion (Global Growth Insights); Approximately US$12.3 billion (Business Research Insights)

- 2025: Approximately US$38.62 billion (Global Growth Insights); Approximately US$12.3 billion (Business Research Insights)

- 2026: Projected approximately US$13 billion (Business Research Insights)

- Growth Rate: Mainstream institutions predict a CAGR of 4.5%-5.71% from 2025 to 2034 - 2034-2035: Market size is expected to reach US$57.4 billion or US$21.44 billion (different institutions' methods)

- Regional Distribution: North America approximately 35%, Europe approximately 29%, Asia Pacific approximately 26%; China approximately US$1.72 billion in 2025 Reasons for the Differences

- Statistical Scope: Does it include chemical recycling/advanced recycling capacity? - Product Category Coverage: Does it include all mainstream product categories such as PET/PP/HDPE?

- Price Calculation: Is the price based on recycled pellets or modified material? Core Drivers - Policy: Mandatory recycling and content requirements such as EU PPWR and US California AB793

- Demand: Sustainability commitments from brand owners, leading to increased usage in packaging, automotive, and home appliance sectors.

- Supply: Upgraded recycling technology, expansion of high-purity PCR material production capacity.

Yujie Industrial is a leading specialized and innovative enterprise in China PCR modification field, boasting outstanding advantages in customization, full-category coverage, international certification, and localized services.

The following explains its core advantages and industry positioning:

Core Advantages

- Comprehensive Certifications: GRS, OBP, UL2809, IATF16949, ISO9001/14001/45001, etc.; TC certificates available; carbon footprint accounting supported.

- Strong Modification Technology: AI sorting + multi-stage filtration + customized formulations, performance close to virgin materials; capable of reinforcement, flame retardancy, antistatic properties, weather resistance, etc.

- Full-Category Coverage: PCR PP/HDPE/PET/ABS/PC/PA, suitable for automotive, home appliance, packaging, textile, and other applications.

- Stable Delivery: Annual production capacity of 50,000 tons; minimum order quantity as low as 500kg; standard delivery time 3-7 days; expedited service available in Fujian.

- Carbon Advantage: PCR PP reduces carbon emissions by approximately 72% per ton, facilitating green label certification. Industry Positioning Yujie is one of the leading professional benchmarks in China's PCR modification field.

- Yujie Industrial is highly competitive in its combination of PCR modification, customization, certification and traceability, and localized services, serving brands such as IKEA, Walmart, BYD, Xiaomi, Foxconn, Deli, and Jabil.

Thank you for reading. Yujie Industrial website: www.yujiepcr.com

Best regards,

We can modified and customized for you .

Please feel free to contact us. Thank you !

William Chen Whatsapp/Wechat: +8613030895350 Email:13030895350@163.com

Yujie Industrial materials for home appliances are based on PCR-modified recycled materials, including PCR-PP (flame retardant/temperature resistant/food grade), PCR-ABS/PC-ABS, PCR-PC, PCR-TPU, PCR-PA6/66, and halogen-free flame retardant PCR-HIPS.

The recycled content is ≥90%, and the materials have obtained full certifications including GRS/ISCC/UL2809/FDA/LFGB/REACH/RoHS. Suitable for both large and small home appliances and consumer electronics, these materials offer flame retardancy, insulation, temperature resistance, impact resistance, low carbon footprint, environmental friendliness, and process compatibility, requiring no major mold modifications.

I. Core Application Scenarios (by Product Category)

Major Appliances

White Goods: Washing machine inner drum lid, air conditioner fan blades/air guides, refrigerator drawers/shelves, freezer door seals/frames, compressor sound insulation covers Major Kitchen Appliances: Dishwasher outer shell/inner container accessories, sterilizer shelves, steam oven outer shell/door handles, integrated stove panel.

Small Kitchen Appliances

Cooking Appliances: Coffee maker/bread maker outer shell, juicer cup body, electric kettle body/lid, air fryer outer shell/knob Small Kitchen Appliances: Kitchen scale outer shell, food processor accessories, blender base, rice cooker/pressure cooker outer shell, knife handles

Cleaning and Care Appliances

Cleaning Appliances Appliances: Vacuum cleaner housing/hose connector, robot vacuum housing/side brush holder, mop handle, trash can body/lid

Personal Care Appliances: Hair dryer housing/nozzle, hair straightener/curling iron housing, electric toothbrush base, shaver housing/stand

Consumer Electronics & Lighting

Charging Devices: Charger housing, power adapter housing, power bank housing, data cable connector protective sleeve Lighting Appliances: LED lamp holder/lampshade, smart light housing, switch panel, pendant light decorative parts Small Electronics: Remote control housing, smart speaker housing, camera housing, electronic scale housing

II. Material-Scenario-Core Performance Selection Table

Material Type Typical Applications, Core Performance Requirements, and Appliance Compatibility Advantages

Flame-retardant/Temperature-resistant PCR-PP: Washing machine inner tub lid, air conditioner fan blades, electric kettle base. Flame retardant UL94 V0, temperature resistance -30℃~120℃, impact resistance ≥10kJ/m². Suitable for high temperature/humidity, insulating and flame retardant, high cost-performance ratio.

PCR-ABS/PC-ABS: Coffee machine housing, TV housing, robot vacuum cleaner housing. High gloss, dimensional stability, scratch resistance, chemical resistance. Excellent appearance and texture, suitable for complex structures, long-term stability.

PCR-PC: Lampshades, transparent water cups, juicer cups. Light transmittance ≥88%, impact resistance, temperature resistance ≥120℃. Transparent and drop-resistant, suitable for lighting/food contact scenarios.

Halogen-free Flame-retardant PCR-HIPS: Charger housing, remote control housing, small appliance housing. Flame retardant UL94 V0, high flow, easy to process. Environmentally friendly and halogen-free, high molding efficiency, suitable for electronic insulation.

PCR-TPU: Seals, handle covers, shock-absorbing feet. High elasticity, wear-resistant, non-slip, and oil-resistant; leak-proof, shock-absorbing, and noise-reducing; enhances grip comfort.

PCR-PA6/66 (fiber-reinforced) Appliance brackets, load-bearing components, connectors. High strength, fatigue-resistant, and creep-resistant. Suitable for high-frequency stress; will not loosen after long-term use.

III. Core Advantages in the Home Appliance Industry

1. Safety and Environmental Protection: Medical-grade cleaning and disinfection; FDA/LFGB food contact certification; recyclable content ≥90%; carbon emissions approximately 559kg CO₂e/ton; provides carbon footprint and TC certificates, supporting brand ESG and carbon neutrality.

2. Performance Customization: Adjustable melt flow index, flame retardant rating (UL94 V0-V2), temperature resistance (-30℃~120℃), impact resistance; supports antibacterial, antistatic, and scratch-resistant modifications to meet the needs of various home appliance scenarios.

3. Process Compatibility: Mainstream injection molding, supports two-color injection molding/overmolding, good compatibility with virgin materials, no mold/process modification required, suitable for large-scale mass production.

4. Durable and Easy to Maintain: All series are water-resistant, oil-resistant, and detergent-resistant, with high color fastness, long-term use without fading or deformation, suitable for high-frequency use and cleaning needs of household appliances.

IV. General Compliance and Process Key Points

- Environmental Compliance: Passed REACH/RoHS, GRS/ISCC/UL2809 recycling certification, FDA/LFGB food contact certification, meeting the latest European and American environmental regulations.

- Processing Technology: Mainstream injection molding, some parts support extrusion/blow molding, good processing fluidity, high finished product yield.

- Practical Features: Supports multi-color customization, high color fastness, suitable for the appearance design needs of household appliances.

Yujie PCR website : www.yujiepcr.com

Thank you for reading!

In September 2020, China explicitly proposed the goals of "carbon peaking" by 2030 and "carbon neutrality" by 2060, advocating a green, environmentally friendly, and low-carbon lifestyle.

These dual carbon goals accelerate the pace of carbon emission reduction, which is conducive to guiding green technology innovation and enhancing the global competitiveness of the country's industries and economy.

In June 2022, the Guangdong Provincial People's Government issued the "Implementation Plan for Carbon Peaking in Guangdong Province," which proposed promoting carbon peaking actions in the petrochemical industry and promoting the application of technologies and equipment such as raw material optimization, material recycling, and process reengineering.

Recently, the "Interpretation of the Plan" released by the Guangdong Provincial Development and Reform Commission proposed that the circular economy contribute to carbon reduction efforts, establishing and improving a resource recycling system and promoting the reduction and resource utilization of waste.

As a national high-tech enterprise, Yujie Industrial responds to the call of the state and government, contributing to low-carbon actions in the plastics manufacturing field by optimizing raw materials and recycling materials.

Yujie recycles, screens, cleans, modifies, and synthesizes waste materials such as post-consumer plastics and marine plastics. After process reengineering, these waste materials are reprocessed into plastic raw materials that re-enter the market.

Furthermore, Yujie optimizes its plastic raw materials, synthesizing environmentally friendly plastics containing grain fiber, coffee ground fiber, and wood fiber that meet relevant quality standards.

Currently, yujie industrial has assembled a team of experienced and innovative talents, equipped with a modification and innovation factory and a sustainable, circular environmentally friendly materials production workshop. It has developed PCR (post-consumer recycled) environmentally friendly modified plastic products such as RPP, RPE, RABS, RPET, RPC, RPOM, RPA,RPCTG and RTPE.

Yujie industrial continues to develop a series of products with scratch resistance, injection molding properties, cold resistance, weather resistance, and fire resistance. It also has significant technological advantages in product color matching and development, meeting the high-performance product needs of industries such as automotive manufacturing, medical, and electronics.

Yujie industrial has successively passed various professional international system certifications, including ISO9001, ISO14001, IATF16949, GRS, UL2809, ISCC and OBP marine recycling.

Yujie Industrial has consistently put its business philosophy of "quality, responsibility, innovation, and sharing" into practice, and adheres to the social belief of "win-win cooperation and eternal integrity," striving to become a responsible and trustworthy high-quality enterprise

Yujie Industrial PCR materials models, certifications, and typical cases, balancing performance and compliance.

Below is a summary categorized into food packaging and electronic packaging:

I. Food Contact Packaging Core Models and Characteristics

- PCR-PP (RPP recycled PP) General Grade: Suitable for lunch boxes, beverage bottles, and sauce jars; FDA/LFGB food contact certification, heat resistant up to 120℃, microwave/retortable.

- PCR-PP (RPP recycled PP) High Impact Grade: Used for food storage boxes and turnover boxes; notched impact strength ≥5kJ/m², low temperature resistance -20℃.

- PCR-PE (RPE recycled PE) Film Grade: Suitable for food express bags and food storage bags; excellent blown film properties, uniform thickness, and strong printability.

- PCR-PET (RPET recycled PET) Bottle Grade: Used for beverage bottles and food cans; good transparency, excellent barrier properties, and recyclable. Core Certifications

- Quality and Environmental Protection: GRS, ISCC, OBP, UL2809,carbon footprint traceability.

- Food Contact: FDA 21 CFR 177.1520, LFGB. - Systems: ISO9001, ISO14001, ISO45001. Typical Cases

- Chain Restaurants: Disposable lunch boxes, RPP material, FDA certified, over 80% carbon reduction, annual usage over 5000 tons.

- Food Brands: Sauce jars, condiment boxes, RPP with customized colors, replacing virgin PP, cost reduction of 15%+.

- E-commerce Fresh Food: Food storage bags/films, RPE blown film grade, strong toughness, clear printing, supporting sustainable packaging upgrades for brands.

II. Electronic Packaging Core Models and Characteristics

- RPP Flame Retardant Grade: Electronic component trays, turnover boxes; UL94 V0, heat resistant to 100℃, good insulation.

- PCR-ABS (RABS) High Rigidity Grade: Electronic casings, adapter casings; tensile strength ≥40MPa, dimensional stability, precision injection molding possible.

- PCR-HIPS (RHIPS) Antistatic Grade: Electronic cushioning liners, packaging pallets; surface resistivity 10⁸-10¹⁰Ω, prevents static charge buildup.

- PCR-PC (RPC) Transparent Grade: Used for packaging optical and electronic components; light transmittance ≥85%, impact resistant, aging resistant.

Yujie Industrial Core Certifications

- Environmental Protection and Carbon Footprint: GRS,OBP, ISCC, UL2809 (carbon reduction certification).

- Electronic Compliance: RoHS, REACH (Restriction of Hazardous Substances).

- Flame Retardancy and Safety: UL94 V0 (flame retardant), IATF16949 (applicable to automotive electronics).

Typical Cases

- Electronic Component Manufacturer: Capacitor packaging pallets, RPP flame retardant grade, UL94 V0, RoHS compliant, annual usage exceeding 3000 tons.

- Home Appliance Brand: Air conditioner/washing machine components, RABS high-rigidity grade, replacing new materials, reducing costs by 20%, carbon reduction exceeding 70%.

- 3C accessory manufacturers: Adapter housings, RPC transparent grade, 88% light transmittance, impact resistant, meeting environmental and aesthetic requirements.

III. Core Advantages and Selection Recommendations

- Performance: Modified RPP has mechanical properties and heat resistance comparable to virgin materials, supports precise color matching, and ensures accurate color difference control.

- Carbon Reduction: RPP reduces carbon emissions by over 80% compared to virgin materials, contributing to the "dual carbon" goal.

- Selection Recommendations: For food packaging, prioritize RPP/FDA certification; for electronic packaging, prioritize RPP flame retardant grade/RoHS; for films, choose RPE; for transparent containers, choose RPET.

Green circular packaging, the first batch of packaging bags made of PCR RHDPE material produced by YuJie Industrial was used for the export packing of PCR RPP materials.

Achieving green and low-carbon circular utilization.

Yujie website: www.yujiepcr.com

Best regards,

We can modified and customized for you .

Please feel free to contact us. Thank you !

William Chen Whatsapp/Wechat: +8613030895350 Email:13030895350@163.com

Yujie Industrial's RPP (PCR-PP/recycled polypropylene pellets) is a compliant and environmentally friendly raw material in IKEA's sustainable supply chain, compatible with its procurement standards for plastic parts.

Yujie Industrial's innovative PCR materials and application cases have all passed GRS global recycling standards, OBP Ocean Bound Recycled plastics certification, and IATF16949 automotive quality system certification. Its technological achievements help clients meet the requirements of the EU's Circular Economy Action Plan (CEAP). For example, the PCR material project in cooperation with IKEA reduced carbon emissions by 2.4 tons per ton of product, becoming a recommended case by the United Nations Environment Programme (UNEP).

Yujie website: www.yujiepcr.com

Key points are as follows:

1. Supply Positioning: Yujie RPP (including ocean bound recycled polypropylene pellets) is certified by GRS/UL2809/OBP, etc., and can issue TC traceability certificates, meeting IKEA's requirements for carbon reduction and traceability of recycled materials, and is compatible with its sustainable procurement system.

2. Material Solution: Using post-consumer recycled PP pellets(such as waste lunch boxes and appliance casings) as raw material, physical modification is applied to make its mechanical/processing properties approach those of virgin materials. Customization options such as toughening, weather resistance, dyeing, and flame retardancy can be provided according to IKEA's needs.

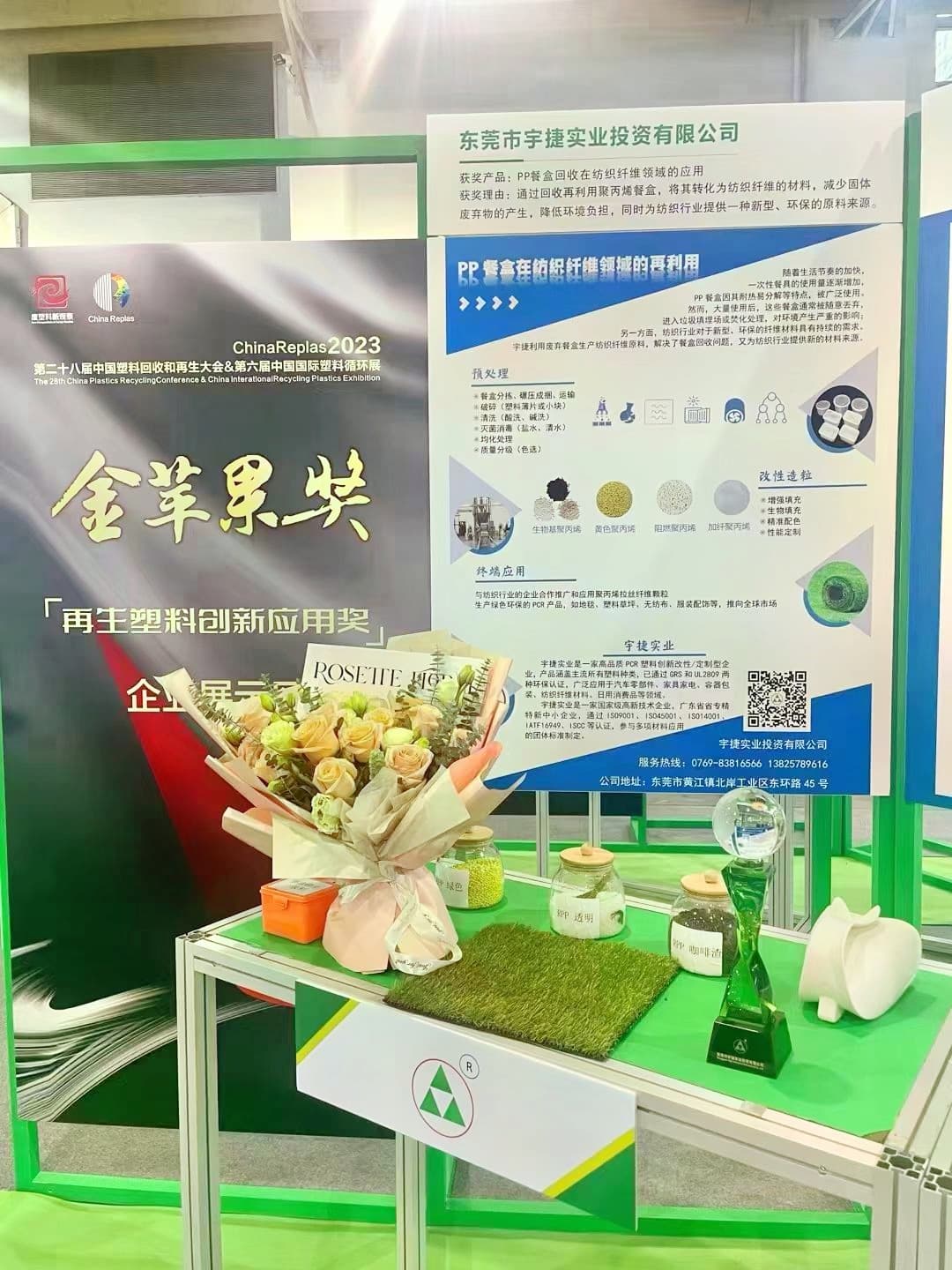

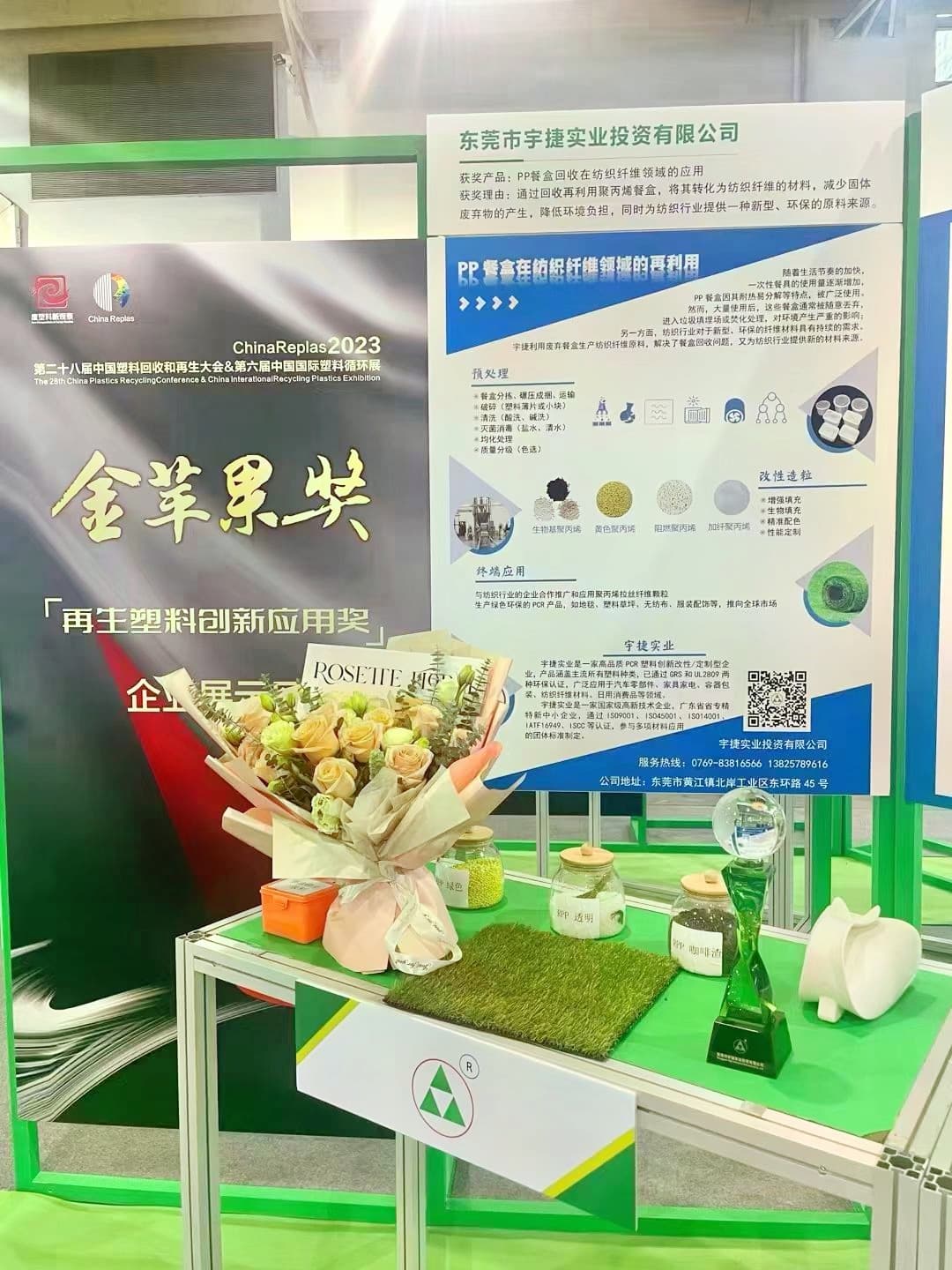

3. Applications and Projects: Yujie Industrial application of Ocean Bound Recycled PP Plastic in Eco-friendly," participated in the 2024 and the 2025 "Golden Apple Award," demonstrating its technological and environmental implementation capabilities in the hanger scenario. Its PCR-PP(post consumer recycled PP pellets) is also used as the fiber raw material for some of IKEA's polypropylene carpets, indirectly confirming the supply chain partnership.

The value of the cooperation is as follows:

1. Compliance and Certification: Full-chain traceability, aligning with IKEA's recycled material procurement and carbon reduction goals.

2. Performance and Cost: Physically modified PCR-PP offers performance comparable to virgin materials, combining cost advantages with low carbon emissions (approximately 72% carbon reduction per ton of PCR-PP).

3. Customization: Hangers can be modified to meet specific needs regarding load-bearing capacity, weather resistance, and color, and are compatible with injection molding/wire drawing processes. Yujie Industrial is committed to promoting sustainable development.

PP granules are the mainstream raw material for clothes hanger production, primarily injection molding grade with a small amount of fiber grade. They combine lightweight, a balanced rigidity and toughness, ease of processing, and low cost, making them suitable for household, supermarket, and hotel hanger applications. Recycled PP (such as PCR-RPP) also contributes to environmental protection and carbon reduction.

1、 Common PP Granule Types and Characteristics

Homopolymer PP: High rigidity, good gloss, low shrinkage, suitable for basic clothes hangers; the disadvantage is low-temperature brittleness, requiring toughening modification.

Impact Copolymer PP: Ethylene copolymerization improves toughness and drop resistance, suitable for adult/thickened clothes hangers with a hanging weight ≥5kg.

Modified PP: Talc filler for increased rigidity, POE for toughness, antioxidants/UV agents for improved weather resistance, meeting customized needs such as anti-slip/aging resistance/flame retardancy (V0 grade).

Recycled PP (PCR-RPP): Post-consumer recycled material, physically modified to match the performance of virgin materials, GRS/OBP certified and traceable, contributing to carbon reduction of approximately 72%/ton, suitable for brand environmental procurement.

Key Indicators: Tensile strength ≥25MPa, Flexural modulus ≥1200MPa, Notched impact strength ≥5kJ/m², Heat resistance ≥80℃, Load capacity ≥5kg, Shrinkage 1.5%–2.5%.

2、 Production Process and Parameters

Mainstream Process: Injection molding (clothes hanger body/hooks), a small amount of brushed grade used for crossbars/support strips.

Injection Molding Window: Material temperature 180–220℃, mold temperature 20–40℃, holding pressure 50–80MPa, cycle time 15–30 seconds; talc/glass fiber can be added as needed to reduce shrinkage and improve dimensional stability.

Post-processing: Gate removal, edge trimming, sanding/spraying with anti-slip coating to improve user experience.

3、 Application Scenarios and Selection

Household Clothes Hangers: Homopolymer/Copolymer PP, toughened and weather-resistant, load-bearing capacity 5–8kg, rich color options.

Supermarket/Fast Fashion Clothes Hangers: PCR-RPP (GRS certified), traceable, meets brand sustainability requirements.

Hotel/Public Area Clothes Hangers: Flame-retardant modified PP (V0 grade), meets fire safety standards.

Trouser Hangers/Clothes Clips: High-toughness PP, resistant to repeated opening and closing, optional anti-slip texture.

Our products are not just plastic, but also a link between people and nature, the present and the future. We firmly believe that by adhering to the concept of green development and through continuous innovation and progress, we can create a cleaner and healthier environment for future generations.

Thank you for your patience in reading.

If you found this article helpful, please share it.

Please feel free to contact us. Thank you.

Best regards!

William Chen Whatsapp\Wechat: +086 13030895350 Email: 13030895350@163.com

Mr. Shi from Yujie Industrial, a leading plastics supplier, was invited to participate in a live broadcast on Plus.com, where he discussed the development and business opportunities of the PCR industry with Dr. Zhang. During the broadcast, Mr. Shi shared the reasons for the rise and current status of the PCR industry, analyzed potential market opportunities and bottlenecks, recounted Yujie's efforts, trials, and achievements, and expressed his vision for future development. Finally, he and Dr. Zhang called on more businesses to fulfill their social responsibility, pay attention to the PCR industry, reuse misused resources, and jointly protect our green planet.

Recently, more and more manufacturers, traders, and brand owners have begun to pay attention to PCR, GRS, UL2809, and OBP, and have many questions about them. Yujie began focusing on environmental certification early on and was among the first companies to obtain GRS certification. It has successfully launched innovative PCR products to the market, driving the development of the PCR plastics industry. Now, let's follow Yujie to understand what PCR, GRS, OBP, and UL2809 are, and the connections between them.

In simple terms, PCR (Post-Consumer Recycled Material) is a general term for post-consumer recycled and reused goods, while GRS (Good Supply Practice) and UL2809 are two environmental certification methods for recycled products, both providing supply chain traceability certification. OBP (Onshore Plastics Product) specifically refers to marine waste plastics. GRS certification is mature, widely recognized in the global market, and has high acceptance. UL2809 emphasizes the verification of the content of recycled materials in products. Focusing on the PCR industry can help us enter high-value markets and gain the attention of environmentally conscious consumers, enhancing our market competitiveness.

PCR – Post-Consumer Recycled Material

Recyclable plastics generally come in two types: one is plastic products recycled and reused after consumer use, i.e., PCR plastics; the other is waste generated during industrial production, commonly known as sprue, i.e., PIR plastics (post-industrial recycled material). Both are recycled plastics. PIR plastics are easier to process, generally requiring immediate crushing to regenerate pellets; PCR plastics have an absolute advantage in terms of the quantity that can be recycled. A vast amount of waste plastic worldwide awaits recycling and reuse, posing a significant challenge to production processes and procedures.

For many years, through unwavering investment in the PCR industry, Yujie has cultivated a highly skilled and experienced team, equipped with sustainable and environmentally friendly material production workshops, and continuously improved its production processes and procedures to maximize the restoration of the original properties of plastics. After initial sorting, recycled plastics undergo crushing, brine washing, and high-temperature washing before being mixed in a large mixing tank for the first time. The mixed material undergoes its first testing and grading, is packaged for later use, and qualified plastics are placed on the production platform where additives are added for a second mixing. The mixed plastics are then granulated in an extruder, undergoing dehydration, drying, and vibration processes before a third final mixing. The finished product undergoes a second testing; qualified products are packaged and shipped, while unqualified products are returned to the warehouse. It is through these three mixing processes and two testing processes that the original properties of the raw materials are preserved. Currently, Yujie can provide customized modification and dyeing services for recycled plastics and is capable of producing high-quality PCR series products with properties comparable to the raw materials. The PCR series is widely used in consumer electronics and office equipment, furniture and appliances, automotive parts, textiles, packaging, and other fields.

GRS – Global Recycled Standard

GRS certification is an international, voluntary, and comprehensive product standard that specifies third-party certification requirements in four areas: recycling content, chain of custody, social and environmental practices, and chemical restrictions. It aims to increase the use of recycled materials in products and reduce/eliminate the hazards caused by their production. It applies to products with a recycled content of 20% or more. GRS certification spans the entire supply chain, connecting all stakeholders, including raw materials, production, processing, trade, and branding. All parties participate, starting from the recycling stage, with each production stage undergoing certification, ultimately ending with the final seller in business-to-business transactions. Transaction Certificates (TCs) are used to trace the origin of materials between upstream and downstream entities.

Yujie has already obtained GRS certification this year, covering almost all major plastic types, and has become an IKEA supplier. We welcome your feedback.

Ocean Bound Plastic refers to plastics that are not properly managed, are abandoned, and transported to the ocean by rain, wind, tides, rivers, and floods, in communities or areas where waste management is lacking or extremely inefficient. Plastic waste in landfills or managed landfills is not considered OBP. To more precisely target the points of marine plastic spills in the ocean, marine plastics are subcategories: waterway marine plastics (plastic waste located in or within 200 meters of rivers) and shoreline marine plastics (plastic waste located within 200 meters inland from the highest tide line and within 100 meters outward from the lowest tide line). OBP aims to encourage the removal of marine plastics from the environment by increasing the value of effective collection and treatment. Yujie's PCR series products also include marine recycled plastics and have received professional certification.

UL 2809 – UL's Verification Statement Regarding Recycled Material Content

UL is an international third-party certification, auditing, testing, and standards development body, offering verification statements for various categories. The UL Environmental Declaration verification verifies specific environmental indicators of a product. Qualified companies or manufacturers can use the UL Environmental Declaration verification mark on product packaging and marketing materials. Verification includes aspects such as bio-based content, recyclable material content, fast-recycling materials, zero waste landfill, and VOC content. The UL Environmental Product Declaration Mark, developed according to the Product Category Rules (PCR), provides manufacturers with a reliable environmental transparency report containing environmental information throughout the product's entire life cycle (LCA), from material selection to post-use disposal. The UL 2809 certificate is a declaration of environmental verification of a product's recycled material content. It involves third-party verification of the product's pre-consumer recycled material content, post-consumer recycled material content, closed-loop recycled material content, total recycled material content, and ocean recycled plastic content to prove that the product is as environmentally friendly as claimed.

Yujie has four PCR products that have obtained UL 2809 certificates: RPC XL110, RABS XL700, RPC/ABS XL1200, and PBT PB010. PCR products contain 63% to 93% recycled materials, including post-consumer recycled plastics derived from electronics and ocean-recycled plastics. While increasing the recycled material content, the performance of the new plastics is excellent, comparable to the raw materials. They have also passed the EU's RoHS (Hazardous Substances in Electronics and Information Technology) testing and almost all industry-specific chemical testing (ReacH) standards, making them applicable to electronics, building materials, automotive parts, medical devices, and other fields.

The global rise of the PCR industry and various environmental certifications demonstrates that the circular economy, as the foundation of human survival, has become a widely accepted consensus. People's awareness of resource recycling and sustainable development is rapidly increasing, and material reuse has become an important way to rationally utilize resources, replace other products, and reduce environmental pollution. Countries around the world are enacting legislation to increase the recycling rate of materials and using economic means to encourage the reuse of recycled resources and the development of related technologies. Environmentally friendly products are more easily accepted by consumers, better meet people's growing demands for environmental protection, gain a broader market, and possess brand value.

Yujie Industrial's PCR product series has passed GRS and UL2809 certifications, fully guaranteeing the source and quality of these products. This provides downstream buyers and brand owners with reliable product assurance, meeting market demand for high-quality PCR products. Of course, Yujie will not stop there; it will continue to move forward, driving the development of the PCR industry, fulfilling its corporate social responsibility, and contributing to a greener planet.

Thank you for reading! Thank you for your support!

Best regards,

We can modified and customized for you .

Please feel free to contact us. Thank you !

William Chen Whatsapp/Wechat: +8613030895350 Email:13030895350@163.com

- Bismaleimide Series2

- Cross-Linking agent / Vulcanizing Agent1

- Curing Agent1

- Engineering Plastic Pellets4

- Epoxy Resin2

- Ethylene-VinylAlcohol Copolymer(EVOH)1

- Fish Oil1

- Food Additives3

- Glucosamine1

- Heat-resistant modifier series1

- High Assay Quaternary Ammonium Compounds9

- Low Assay Quaternary Ammonium Compounds13

- Modified Polyvinyl Alcohol1

- Monomalemide Series2

- Other Surfactants/Catalysts8

- Plastic Random Packing1

- Plastic Structured Packing1

- Polyacrylamide1

- Polyurethane Resin2

- Polyvinyl Alcohol (PVA)2

- Power Coatings3

- Quaternary Ammonium Hydroxide4

- Special Quaternary Ammonium Compounds7

- TPU4

- Tertiary Amines1

- UV Ink1

- VAE Emulsion (Vinyl Acetate–ethylene Copolymer Emulsion)1

- aluminum paste1

- antiform2

- fire sleeve2

- resin2