Stains, Impurities, and Foreign Substances

The plastic material is impure or contaminated.

2025-11-07

In the grand landscape of modern electronics, ceramic substrates, though often operating behind the scenes, play an indispensable and critical role. From high-frequency signal transmission in 5G base stations, to motor controllers in new energy vehicles, and further to the core packaging layers of power semiconductors, ceramic substrates are consistently stationed at the heart of electronic components. They silently shoulder the dual mission of acting as the "Thermal Backbone" and "Insulation Guardian."

Taking 5G base stations as an example, their operation generates significant heat. If this heat is not dissipated promptly, device performance can drastically degrade, potentially leading to failures. Leveraging their exceptional thermal conductivity, ceramic substrates can rapidly transfer heat away, ensuring stable base station operation. Within the motor controllers of new energy vehicles, ceramic substrates must not only endure high-temperature environments but also withstand the challenges of high voltage and high current. Their superior insulation properties and mechanical strength provide reliable assurance for the efficient operation of the motors.

According to forecasts from authoritative institutions, the global ceramic substrate market is projected to soar from USD 1.13 billion in 2022 to USD 4.15 billion in 2029, achieving a remarkable compound annual growth rate (CAGR) of 18.23%. Behind this rapid growth lies the explosive demand from sectors such as power electronics, third-generation semiconductors, and high-end equipment. With the rapid advancement of technology, the performance requirements for electronic components in these fields are increasingly stringent, and the importance of ceramic substrates as a key material is becoming ever more prominent.

About Xiamen Juci Technology Co., LTD

Juci provides high-quality AlN ceramic substrates, structural parts, and heat sinks. These products are vital solutions for thermal management challenges in cutting-edge industries such as 5G communication, new energy vehicles, and high-power LED packaging.

Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com

2025-11-07

Today, with the continuous increase in the power density of electronic devices, heat dissipation has become one of the key bottlenecks restricting technological development. Traditional thermal interface materials are gradually unable to meet the demands of efficient heat dissipation. Nitride ceramic fillers, especially aluminum nitride (AlN), hexagonal boron nitride (h-BN), and silicon nitride (β-Si₃N₄), are emerging as new research and application focuses due to their outstanding thermal conductivity and comprehensive physical properties.

Aluminum nitride (AlN) is regarded as an ideal material for the next generation of heat dissipation substrates and electronic device packaging due to its excellent thermal conductivity (theoretical thermal conductivity of 320 W·m⁻¹·K⁻¹), reliable electrical insulation, low dielectric constant and dielectric loss, as well as a coefficient of thermal expansion (CTE, 4.5 × 10⁻⁶ °C⁻¹) that matches that of silicon.

Hexagonal boron nitride (h-BN), with its wide bandgap (5.2 eV), high thermal conductivity (theoretical thermal conductivity of 2000 W·m⁻¹·K⁻¹), and low density (2.3 g·cm⁻³), has a hexagonal ring network structure similar to graphene and is often referred to as "white graphene." Coupled with its excellent lubricity and chemical stability, it has gradually become a major focus in the field of thermal interface materials.

Polymer composites using BN as a nano-filler can simultaneously achieve high thermal conductivity, low CTE, and high electrical resistance, meeting the urgent demands of new high-efficiency thermal management materials. Additionally, β-Si₃N₄ as a filler facilitates the formation of a particle network, enhancing thermal conductivity while maintaining good mechanical and thermodynamic stability.

Nitride ceramic fillers exhibit exceptional intrinsic thermal conductivity, making them a key research direction in the laboratory development of ultra-high thermal conductivity thermal interface materials. However, the preparation of nitrides is relatively challenging and costly, particularly for nitride fillers with high application value and specific shapes, such as spherical AlN, BN nanosheets/nanotubes, and β-Si₃N₄ whiskers. Achieving low-cost, efficient, and industrial-scale mass production remains one of the important research topics.

About Xiamen Juci Technology Co., LTD

Xiamen Juci Technology Co., Ltd. is a leading Chinese manufacturer specializing in aluminum nitride ceramic fillers. Our filler product line includes two series: aluminum nitride single crystal filler and aluminum nitride ceramic microspheres. Known for their high purity, narrow particle size distribution, and excellent thermal conductivity, these materials have established us as a trusted thermal management solutions provider for clients worldwide.

Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com

2025-11-07

Customer Project:

PA6-LGF40 Solution for Aluminum Cutting Machine

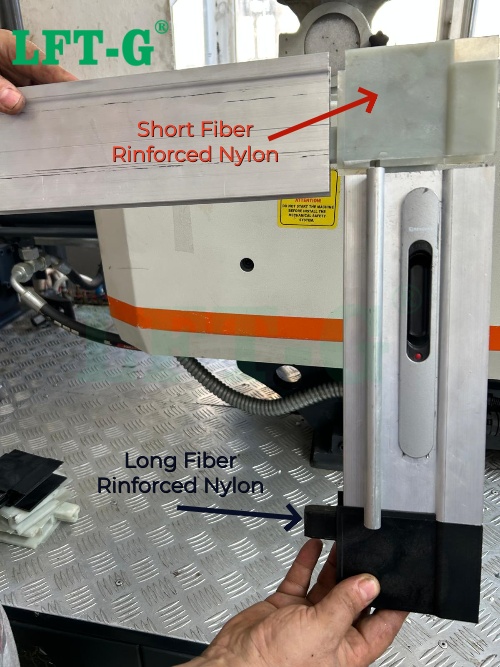

In this project, PA6 filled with 40% long glass fiber (PA6-LGF40) was chosen to replace the short glass fiber reinforced material for the end support block of an aluminum profile cutting machine positioning stop. The black component serves as a structural support part, requiring excellent mechanical strength, dimensional stability, and long-term durability under repeated impact and vibration.

Project Background

The positioning stop of an aluminum profile cutting machine plays a crucial role in ensuring cutting accuracy and stability. Traditionally, the end support block of the stop was made from short glass fiber reinforced nylon, which often suffered from deformation, wear, and reduced precision after long-term use due to continuous vibration and impact during operation.

To improve durability and maintain dimensional stability, the client sought a material solution that combined high strength, stiffness, and long-term reliability without increasing weight or compromising processability.

Material Advantages

PA6-LGF40 demonstrated the following key advantages:

- High Strength & Stiffness: The long glass fibers form a continuous reinforcing network, significantly enhancing mechanical performance and load-bearing capacity, ensuring structural stability under repeated mechanical stress.

- Impact & Fatigue Resistance: The material maintains its mechanical integrity even under repeated cutting vibrations, preventing cracking or deformation over time.

- Dimensional Stability: The component retains accurate geometry during long-term use, ensuring consistent positioning accuracy and reducing the need for maintenance or recalibration.

- Lightweight & Processability: Compared with metal or overly dense composites, PA6-LGF40 achieves a balance between strength and weight, while still being easy to mold and assemble.

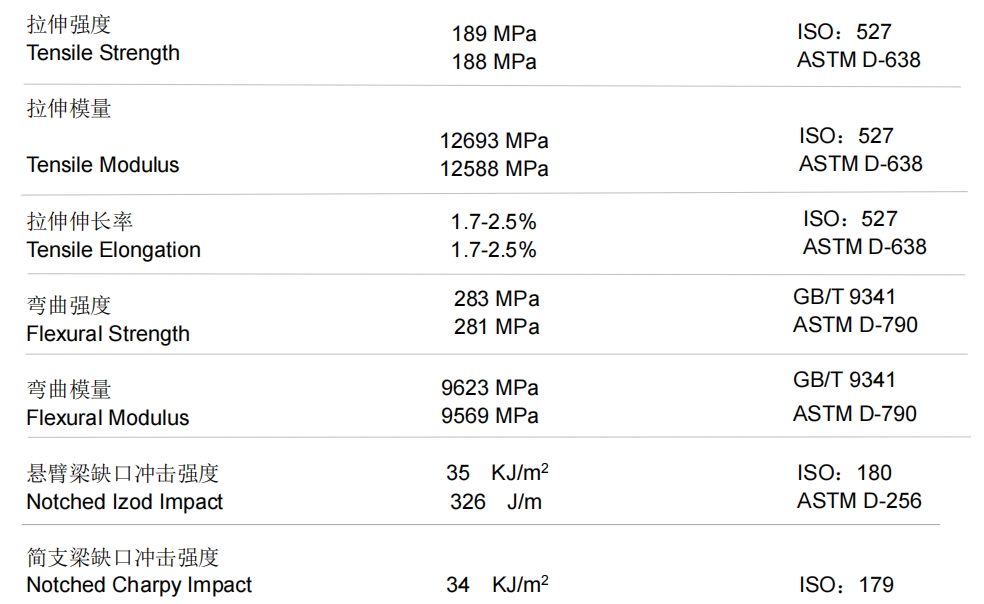

Datasheet for LFT PA6-LGF40

Customer Benefits

By switching to PA6-LGF40, the customer obtained a high-performance structural component that provides superior mechanical strength, impact resistance, and dimensional stability compared to the previous short glass fiber material.

The improved toughness and long-term durability of the positioning stop ensure stable cutting accuracy, reduced deformation, and longer service life of the equipment.

Additionally, the enhanced wear resistance and reliability significantly lower maintenance frequency and overall operating costs, while maintaining lightweight performance.

Conclusion

This project demonstrates the successful replacement of a short glass fiber reinforced nylon component with PA6-LGF40 long glass fiber composite in an aluminum profile cutting machine positioning stop.

The upgrade not only improved mechanical performance and durability but also exemplifies the practical application of “plastic replacing metal” and “long fiber replacing short fiber” concepts in industrial equipment components, delivering both technical and economic advantages.

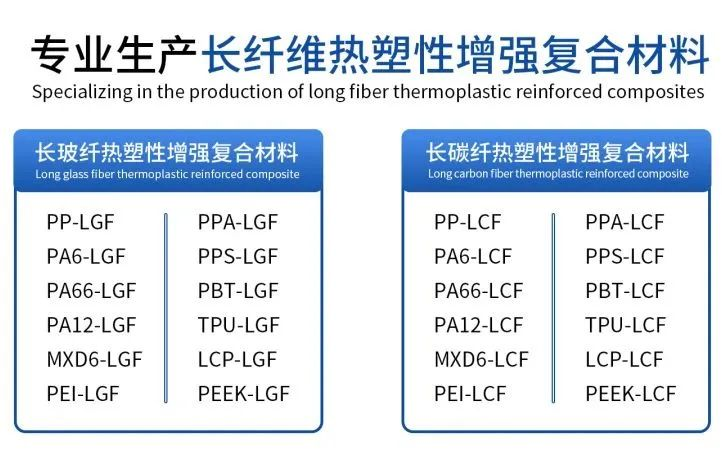

About Us

Xiamen LFT Composite Plastic Co., Ltd. (LFT-G) is a global leading manufacturer of long fiber reinforced thermoplastic (LFT) materials. With our R&D, we specialize in research, development, and production of high-performance composite solutions, including PA, PP, TPU, PEEK, PPS, and PPA filled with long glass fiber or long carbon fiber.

Our materials are widely applied in automotive, electronics, power tools, and industrial components, offering exceptional strength, impact resistance, dimensional stability, and "plastic replacement for steel" capabilities.

Committed to innovation and sustainability, LFT-G integrates advanced technology with customer-focused service, delivering tailored solutions that meet the most demanding requirements while reducing weight, enhancing durability, and ensuring cost efficiency.

2025-11-07

Poor Transparency:

Due to poor contact between the molten material and the mold surface, tiny pits appear on the surface of the molded part, causing light scattering. Alternatively, the mold surface may not be sufficiently polished, resulting in decreased or uneven transparency in transparent products.

| 22.1 Causes | 22.2 Solutions |

|---|---|

| 22.1.1 Low mold temperature or low material temperature, causing poor contact between molten material and mold surface. | 22.2.1 Increase mold and material temperatures to ensure full contact between the melt and mold surface. |

| 22.1.2 Dull mold surface, oil, or moisture contamination. | 22.2.2 Clean the mold surface to remove oil and moisture, or polish the mold surface. |

| 22.1.3 Excessive or inappropriate mold release agent. | 22.2.3 Use a suitable release agent or reduce the amount sprayed. |

| 22.1.4 High material temperature or excessive shear in the gating system causing material decomposition. | 22.2.4 Lower material temperature and injection speed to prevent material degradation. |

| 22.1.5 High moisture content, impurities, black streaks, or silver streaks in the plastic. | 22.2.5 Dry the material according to requirements and replace any nonconforming material. |

| 22.1.6 Poor plasticizing. | 22.2.6 Adjust processing conditions to ensure uniform plasticization. |

| 22.1.7 Poor or uneven cooling of crystalline materials, or uneven wall thickness of molded parts. | 22.2.7 Ensure uniform cooling for crystalline materials or modify the product design to make wall thickness as even as possible. |

| 22.1.8 Hot runner temperature too high or too low. | 22.2.8 Adjust the hot runner temperature. |

2025-11-07

| 23.1 Causes | 23.2 Solutions |

|---|---|

| 23.1.1 Raw materials, pellets, or pigments are impure. | 23.2.1 Replace the raw materials, dyes, or pigments. |

| 23.1.2 The plastic has decomposed or deteriorated. | 23.2.2 Adjust the processing conditions to prevent material decomposition. |

| 23.1.3 The barrel and hopper are not clean. | 23.2.3 Clean the barrel, hopper, and feeding tube. |

| 23.1.4 Foreign substances mixed in during preheating. | 23.2.4 Prevent foreign substances from entering during drying or material storage. |

2025-11-07

Whitening (Stress Whitening):

During demolding, excessive ejection force is applied to the surface areas around ejector pins or grooves. Due to forced demolding, high internal stress develops in these regions, sometimes causing deformation. Whitening is a sign of stress cracking. Materials such as ABS and HIPS are particularly prone to this phenomenon.

2025-11-07

Dull Surface (Lack of Gloss):

Due to poor mold surface finish, inadequate contact between the molten material and the mold surface, or improper material and mold temperatures, the molded product fails to exhibit the natural gloss of the resin. Instead, the surface appears whitish, cloudy, or dull.

| 21.1 Causes | 21.2 Solutions |

|---|---|

| 21.1.1 Poor mold surface finish; presence of scratches, moisture, or oil contamination. | 21.2.1 Repair or clean the mold surface and wipe the cavity dry. |

| 21.1.2 Excessive or improper use of mold release agent. | 21.2.2 Choose a suitable release agent, apply sparingly, and wipe the cavity if necessary. |

| 21.1.3 Moisture or excessive volatiles in the plastic. | 21.2.3 Dry the material according to process requirements; if necessary, increase drying temperature or extend drying time. |

| 21.1.4 Decomposition or deterioration of plastic or pigment. | 21.2.4 Replace with qualified material. |

| 21.1.5 Poor plastic flowability. | 21.2.5 Use a material with better flowability or increase mold temperature and injection pressure appropriately. |

| 21.1.6 Low material temperature, low mold temperature, or slow injection speed. | 21.2.6 Increase material temperature, mold temperature, and injection speed. |

| 21.1.7 Excessive air in the melt or poor mold venting. | 21.2.7 Increase back pressure appropriately and add venting slots in suitable mold locations. |

| 21.1.8 Injection speed too fast and small gate size causing melt vaporization, resulting in a milky thin layer. | 21.2.8 Reduce injection speed and enlarge gate size to prevent melt vaporization. |

| 21.1.9 Material and mold temperatures too high or too low (each plastic type has an optimal temperature range for gloss; deviations reduce gloss). | 21.2.9 Adjust material and mold temperatures according to the specific resin requirements. |

| 21.1.10 Insufficient feeding or poor plasticization. | 21.2.10 Adjust feed volume to ensure uniform plasticization. |

| 21.1.11 Mixed or incompatible materials. | 21.2.11 Replace with qualified material. |

| 21.1.12 Insufficient draft angle causing poor demolding. | 21.2.12 Increase draft angle to ensure easy ejection of parts. |

| 21.1.13 Low surface hardness of molded parts, prone to scratching and abrasion. | 21.2.13 Design and choose proper packaging to protect product surfaces from friction. |

| 21.1.14 Uneven or oversized pellets. | 21.2.14 Use uniform pellets or adjust processing conditions for even plasticization. |

| 21.1.15 Exposed filler or non-oriented silver flake filler. | 21.2.15 Increase mold temperature to ensure filler is not exposed. |

| 21.1.16 Presence of silver streaks or uneven coloration. | 21.2.16 Ensure proper drying of material, identify cause of color unevenness, and take corrective measures. |

| 21.1.17 Hot runner temperature too high or too low; heater or thermocouple damaged. | 21.2.17 Adjust hot runner temperature or replace heater and thermocouple. |

2025-10-29

Titanium dioxide has the characteristics of high chemical stability, non toxicity, and good photoelectric performance, especially rutile titanium dioxide has high surface activity, which is very suitable for battery material modification. Like polyethylene glycol, the introduction of titanium dioxide is also to compensate for the insufficient energy density and rate performance of lithium iron phosphate itself.

There are three main ways to add titanium dioxide to lithium iron phosphate:

1、 Doping modification. By incorporating nanoscale titanium dioxide particles into the lattice of lithium iron phosphate, a heterostructure can be formed, significantly improving the conductivity of the material. Experiments have shown that doping 1% titanium dioxide can increase the electronic conductivity of lithium iron phosphate by two orders of magnitude and improve rate performance by 15% to 30%.

2、 Surface coating. Titanium dioxide can form a protective film on the surface of lithium iron phosphate particles, reducing direct contact between the particles and the electrolyte, thereby suppressing side reactions such as iron leaching and excessive growth of SEI film, while enhancing electrode water retention capacity and improving battery performance in low humidity environments.

3、 Photocatalytic assisted synthesis. Under ultraviolet light, titanium dioxide generates electron hole pairs, accelerating the redox reaction of the precursor, shortening the hydrothermal synthesis time, and improving the purity of the product. A study has successfully reduced the hydrothermal reaction time from 12 hours to 8 hours.

From a mechanistic perspective, the introduction of titanium dioxide can adjust the band structure of lithium iron phosphate, narrow the band gap, and enhance its response to visible light; Heterojunction interfaces can accelerate electron transfer.

In addition, the rigid structure of titanium dioxide can also buffer volume changes during charge and discharge processes, improving cycle life - for example, the capacity retention rate can still exceed 90% after 2000 cycles.

In practical industrialization, titanium dioxide and polyethylene glycol are often used in synergy. For example, the two together form a "carbon titanium dioxide" double coating structure, which not only improves conductivity but also enhances interface stability, resulting in a first discharge specific capacity of 165mAh/g for lithium iron phosphate, with a capacity decay of less than 5% after 1000 cycles.

But currently, the cost of nano titanium dioxide is relatively high, and the uniformity of dispersion is also a technical difficulty, which requires further optimization through processes such as ultrasound and ball milling. Looking ahead, optimizing process parameters through machine learning, developing low-cost synthesis methods for titanium dioxide, and constructing a ternary composite system of polyethylene glycol titanium dioxide graphene will be important research directions. In addition, efficient recycling technologies for waste lithium iron phosphate batteries containing titanium dioxide also need to be developed.

In summary, titanium dioxide significantly enhances the electrochemical performance and stability of lithium iron phosphate materials through various methods such as doping, coating, and photocatalysis, providing solid support for the further development of power batteries and energy storage systems.

SAT NANO is a best supplier of titanium dioxide powder in China, we can supply 30nm, 50nm, 100nm particle, if you have any enquiry, please feel free to contact us at admin@satnano.com

2025-10-29

The meanings of metamorphic treatment, grain refinement, and primary phase refinement or morphology change are different, and sometimes the term metamorphic treatment is used to summarize these contents.

(1) Deterioration treatment. For simple binary Al Si alloys, such as Z102 containing 11%~13% Si, it is a typical eutectic alloy. Its organization consists of coarse needle shaped (should be layered) silicon and a eutectic of alpha (Al) solid solution, as well as a small amount of block shaped primary silicon (with alloy composition biased towards the upper limit). The mechanical properties of the alloy are not high, with a tensile strength not exceeding 140 MPa and an elongation of less than 3%. If a modifier (2-3%) containing Na or NaF is added to the melt before pouring for modification treatment, it seems that the eutectic point is shifted to the right and the eutectic temperature is lowered after modification treatment, causing the originally slightly hypereutectic alloy to become a hypoeutectic alloy. The primary silicon disappears, the eutectic is refined, and a primary α (Al) solid solution appears. The mechanical properties of the alloy have been improved, with a tensile strength of 180 MPa and an elongation of over 8%. It can even be pressure processed into plates and strips.

Using sodium salt as a modifier is prone to moisture absorption, difficult to store, and difficult to control the amount of sodium added. Castings are prone to porosity, and the duration of the modification effect is short. After the modification treatment is completed, it must be poured within 30 minutes. Later, it was discovered that not only sodium, but also strontium had the same effect and had a long shelf life, known as long-acting spoilage agents. Therefore, using sodium salt (NaF) or Al Sr intermediate alloy, it is obvious that Al Sr intermediate alloy is superior, easy to store, easy to control the amount added, and has a long shelf life.

The effect of adding phosphorus is opposite to that of sodium. Originally a eutectic alloy, it obtains a hypereutectic structure, which increases the amount of bulk primary silicon and improves the wear resistance of the alloy. The eutectic cast aluminum alloy used for producing pistons should be treated with phosphorus modification.

Using antimony for modification treatment does not show significant changes in the alloy casting structure, similar to the unmodified structure. However, after solid solution aging, the structure undergoes significant changes, especially the strength and toughness of the alloy are significantly improved.

(2) Refine grain size. Adding a small amount of titanium to aluminum alloy to refine the alpha (Al) grains can improve both the mechanical properties and processability of the alloy. The process of refining the structure of aluminum alloy by adding titanium is also known as modification treatment.

Grain refining agents must be nucleation promoters. When metals and alloys solidify into crystals, they undergo nucleation and growth processes. The formation of crystal nuclei can be divided into homogeneous nucleation and heterogeneous nucleation. Homogeneous nucleation must ensure that the entire melt has the same degree of undercooling. In actual production, it is impossible to achieve this. There are always places (such as the mold wall) that cool quickly, and some places (such as the center of the casting) that cool slowly, resulting in different degrees of undercooling and varying nucleation times. During production, it is expected to add a substance that can be used as a crystal nucleus to achieve a uniform and fine structure in the casting. Adding a small amount of titanium or a small amount of titanium and boron to aluminum alloy can achieve this goal. In addition, cooling rate is also an important factor, which not only affects nucleation but also controls the growth rate of crystals. Only by considering both nucleation (including external crystal nuclei) and cooling rate can a uniform and fine microstructure be obtained.

(3) Change the initial appearance. There are often primary needle like (flake like) compound phases in aluminum alloys, which have a significant impact on the alloy's properties, especially its mechanical properties. If Al3Fe is a needle like phase, the mechanical properties will decrease. If Fe: Si=4:1, AFeSi phase is formed, which changes the shape and significantly improves the mechanical properties, especially elongation. Adding manganese can also alter the morphology of iron containing phases.

In AI Mg alloys, when the magnesium content is high, the β (Mg5Al8) phase becomes coarse and exists at grain boundaries. Without solid solution treatment, the mechanical and corrosion resistance properties are poor. However, solid solution treatment requires a long time. If a small amount of zirconium is added, the β phase can be refined, which is beneficial for heat treatment.

In aluminum alloys, there are occasionally impurities of low melting point metals (such as Pb, Sn, Bi, etc.) present, which weaken the grain boundaries and cause melting at slightly higher temperatures; For example, aluminum contains sodium, causing "sodium embrittlement". Adding a small amount of rare earth elements to turn these metal impurities into compounds can eliminate the problems present in grain boundaries.

Therefore, it can be said that in the process of melting and casting, the elements or intermediate alloys that can improve the alloy structure, refine the alloy grains, change the size, morphology or distribution of primary phases, and remove harmful phases at grain boundaries are all called modifiers, and this process can be called modification treatment.

SAT NANO is a best supplier of aluminum silicon alloy powder AlSi particle in China, we can offer different mircon particle size, if you have any enquiry, please feel free to contact us at admin@satnano.com

2025-10-29

The demand for conductive paste in the photovoltaic industry and electronic packaging field is undergoing a transformation from high silver content to low silver or even silver free. Although silver powder has excellent conductivity and chemical stability, it is expensive, has limited resources, and is prone to electromigration. In contrast, copper's conductivity is second only to silver and its cost is about 1/100 of silver. Therefore, using low-cost copper powder instead of silver powder has become an important way to reduce costs. However, the surface of copper powder is prone to oxidation to form a thin layer of electrically insulating oxide, resulting in a serious decrease in conductivity and reliability. This makes preventing copper powder oxidation a core technical challenge in achieving the replacement of silver paste with copper paste.

Oxidation mechanism and performance degradation of copper powder

Copper is different from metals such as aluminum and nickel in that it is difficult to form a dense and stable intrinsic passivation layer on its surface. Therefore, the exposed copper surface will be continuously oxidized and corroded by oxygen and water vapor in the air. The smaller the particle size and larger the specific surface area of copper powder, the easier it is to rapidly oxidize to produce products such as cuprous oxide (Cu ₂ O) and copper oxide (CuO). This oxide insulation layer significantly reduces the conductivity of copper powder and hinders particle sintering connection, resulting in degradation of the performance of the conductive paste. Especially during the sintering process of the front electrode of photovoltaic cells (often requiring high temperatures exceeding 500 ℃), if copper powder is not protected, it will be severely oxidized and unable to form a good metal conductive network. In addition, in high temperature and high humidity environments, the growth of oxide layer can also cause the conductivity to deteriorate over time, affecting the lifespan of the device. Therefore, inhibiting surface oxidation of copper powder is crucial for maintaining its conductivity, sintering activity, and long-term stability.

The main methods for surface antioxidant treatment of copper powder

Researchers and engineers have developed various surface antioxidant treatment techniques to address the issue of copper powder being prone to oxidation. Constructing a physical or chemical protective layer on the surface of copper powder can block oxygen contact or passivate active sites, thereby slowing down or even preventing oxidation from occurring. The main methods include organic coating protection, inorganic coating, self passivation alloying modification, and surface reduction passivation treatment. The following text introduces the principles and typical developments of each method separately.

Organic coating protection

Fatty acid and polymer coating: Long chain fatty acids such as oleic acid and stearic acid can bond with copper surfaces through carboxyl groups, forming a hydrophobic organic layer to isolate oxygen and moisture. Soaking copper powder in an oleic acid acetone solution for surface modification treatment can form a protective film of oleate on the surface of the powder. Experiments have shown that the purity and antioxidant properties of fine copper powder treated with this method are improved. Similarly, resins or polymers can also be used to coat the surface of copper powder. For example, the in-situ polymerization of polyaniline on the surface of copper powder to form a conductive polymer coating can effectively improve the antioxidant storage stability of copper powder in air. In addition, adding a certain amount of polymer binder (such as ethyl cellulose, acrylic resin, etc.) to pre coat copper powder during the preparation of conductive adhesive has also been proven to reduce the oxidation of copper powder and extend the shelf life of the slurry.

Silane coupling agent modification: One end of the organic silane coupling agent molecule contains a hydrolyzable silane group, which can react with copper surface oxides/hydroxyl groups to form silicon oxygen bonds, and the other end has an organic functional group to provide hydrophobic protection. The formation of an organic silicon film on the surface of copper powder through silane treatment can have a dual effect of anti-oxidation and improving dispersibility. Introducing silane coupling agent KH-902 into epoxy conductive adhesive to treat copper powder, the results showed that adding 3% significantly improved the oxidation resistance of copper powder during high-temperature curing process, and made the copper powder more evenly dispersed in the colloid. Research has shown that silane coupling agents can effectively inhibit the oxidation of copper powder below about 200 ℃, and their use in low-temperature curing slurry systems can help improve the compatibility and stability of the powder with organic carriers.

Inorganic coating

Precious metal coating: Coating a dense layer of inert metal on the surface of copper powder is an effective means of completely preventing oxidation. Silver coated copper powder has achieved mature technology and application. By chemical displacement plating or chemical reduction plating, silver shell layers of tens to hundreds of nanometers can be deposited on the surface of copper particles, forming a "copper core silver shell" structure. The silver shell layer isolates copper from the environment, greatly enhancing its antioxidant stability, while utilizing the high conductivity of silver to ensure excellent conductivity of the composite powder. Silver coated copper powder is expected to replace most pure silver powder and has been applied in fields such as conductive adhesives, electromagnetic shielding coatings, conductive inks, etc. It has also been used in photovoltaic slurries to achieve a silver reduction solution by reducing the silver content to 20% -50%. Another type is nickel plated copper powder, which can also act as a barrier layer to prevent copper oxidation. However, nickel has lower conductivity, and the thickness of the coating needs to be controlled to balance oxidation resistance and conductivity. In addition, copper thin wires coated with palladium/gold have been maturely applied in electronic packaging. For example, bonded copper wires are often coated with a layer of palladium and extremely thin gold to prevent copper from oxidizing and becoming brittle before high-temperature secondary bonding. Overall, the precious metal coating method has the best antioxidant effect, but still introduces a certain amount of precious metals, resulting in higher costs and precise control of coating thickness.

The application prospects of copper powder in conductive pastes and electronic packaging are broad, but oxidation has been the main obstacle between laboratory achievements and actual products. Recent studies have shown that various strategies such as organic coating, inorganic coating, self passivation alloying, and surface reduction passivation can significantly improve the antioxidant properties of copper powder, enabling it to maintain excellent conductivity within a wide process window. Different methods have their own advantages and disadvantages, and need to be selected or combined for specific applications.

SAT NANO is a best supplier of copper powder in China, we can offer 50nm, 100nm, 200nm, 500nm, 1-3um and 0-15um, if you have any enquiry, please feel free to contact us at admin@satnano.com

Categories:

- Bismaleimide Series2

- Cross-Linking agent / Vulcanizing Agent1

- Curing Agent1

- Engineering Plastic Pellets4

- Epoxy Resin2

- Ethylene-VinylAlcohol Copolymer(EVOH)1

- Fish Oil1

- Food Additives3

- Glucosamine1

- Heat-resistant modifier series1

- High Assay Quaternary Ammonium Compounds9

- Low Assay Quaternary Ammonium Compounds13

- Modified Polyvinyl Alcohol1

- Monomalemide Series2

- Other Surfactants/Catalysts8

- Plastic Random Packing1

- Plastic Structured Packing1

- Polyacrylamide1

- Polyurethane Resin2

- Polyvinyl Alcohol (PVA)2

- Power Coatings3

- Quaternary Ammonium Hydroxide4

- Special Quaternary Ammonium Compounds7

- TPU4

- Tertiary Amines1

- UV Ink1

- VAE Emulsion (Vinyl Acetate–ethylene Copolymer Emulsion)1

- aluminum paste1

- antiform2

- fire sleeve2

- resin2

Tags: