Polyvinyl alcohol (PVA) is a popular water-loving polymer membrane material. It has great use in food packaging, pervaporation, and wastewater treatment because it is chemically stable, resists acids and bases, forms films easily, and is safe to use. Its many hydroxyl groups give it good water-loving and antifouling traits. Still, these same groups cause two main problems: it's not very strong and doesn't hold up well in water. This means it can swell or even dissolve in water, which limits where it can be used.

To address these problems, scientists have tried changing PVA membranes by mixing it with other materials, forming nanocomposites, heating it, chemically crosslinking it, or using a mix of these ways .

1. Physical Modification: Boosting Function and Strength

Physical modification methods, like blending and nanocomposites, are popular because they are simple and easy to scale up for industrial production.

1.1 Blending Modification

Combining things to change PVA films involves mixing materials that work well and mix well with PVA to create the films. Chitosan (CS), for instance, is often used. The best part is that it gives PVA films good germ-killing abilities, greatly stopping or even killing Escherichia coli and Staphylococcus aureus. This helps Polyvinyl alcohol film (PVA film) be used in things like hemostatic dressings. However, the addition of blending materials can sometimes weaken the original mechanical properties of the PVA film, making the balance between functionality and mechanical strength a key challenge in this approach.

1.2 Nanocomposite Modification

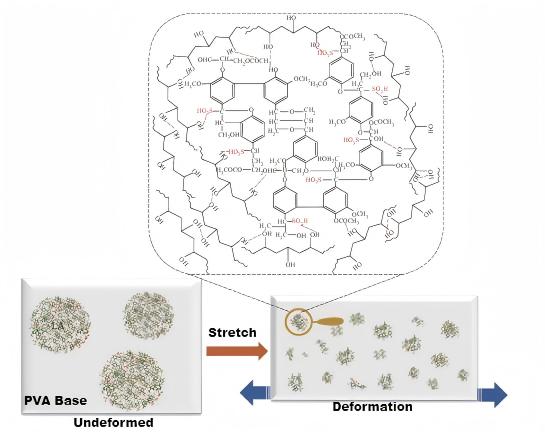

Nanocomposite modification utilizes the unique surface-interfacial effects of nanosized fillers (such as nanosheets, nanorods, and nanotubes) to influence the internal structure of PVA films at the molecular level. Even with a small amount of filler, it can significantly improve the mechanical strength and water resistance of PVA films, while also expanding their electrical conductivity, thermal conductivity, and antimicrobial properties.

- Biopolymer nanomaterials: The addition of nanocellulose (CNC/CNF) and nanolignin (LNA) can improve the mechanical properties of PVA films because they are biocompatible and have good mechanical properties. It has been shown that intermolecular hydrogen bonding between these materials increases the tensile strength and flexibility of PVA films. Nanolignin, especially, does a great job at making PVA films stronger and more resistant to tearing. It also makes them better at blocking water vapor and UV light, which makes them more useful in food packaging.

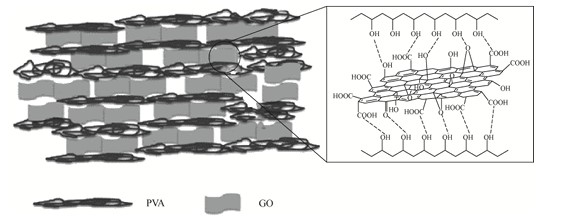

- Carbon-based nanomaterials: Graphene, graphene oxide (GO), and carbon nanotubes (CNTs) possess exceptionally high mechanical strength and excellent electrical and thermal conductivity. GO can form multiple hydrogen bonds with PVA, enhancing both the film's mechanical strength and water resistance. For instance, adding bovine serum albumin to SiO₂ nanoparticles (creating SiO2@BSA) can more than double the tensile strength and elastic modulus of PVA films compared to using pure PVA films. Silicon-based nanomaterials: Silica nanoparticles (SiO2NPs) and montmorillonite (MMT) can effectively enhance the mechanical properties and thermal stability of PVA films. For example, SiO₂ NPs modified with bovine serum albumin (SiO2@BSA) can increase the tensile strength and elastic modulus of PVA films to more than double that of pure films.

- Metal and metal oxide nanoparticles: Silver nanoparticles (AgNPs) impart excellent electrical conductivity and antibacterial properties to PVA films; titanium dioxide nanoparticles (TiO2NPs) significantly enhance the photocatalytic activity of PVA films by reacting with hydroxyl groups on PVA molecular chains, showing great potential for wastewater treatment.

2. Chemical and Thermodynamic Approaches: Building a Stable Structure

2.1 Chemical Crosslinking Modification

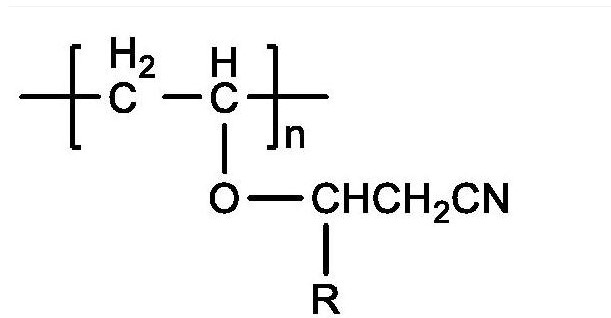

Chemical crosslinking modification utilizes the numerous hydroxyl groups on PVA side chains to react with crosslinkers (such as dibasic/polybasic acids or anhydrides) to form a stable chemical bond (ester bond) crosslinking network between polymer chains. This method can more consistently improve the mechanical properties and water resistance of PVA film, significantly reducing its solubility in water and water swelling. For example, using glutaric acid as a crosslinker can simultaneously improve the tensile strength and elongation at break of PVA film.

2.2 Heat Treatment Modification

Heat treatment controls the movement of PVA molecular chains by adjusting temperature and time, optimizing the internal structure and increasing crystallinity.

- Annealing: Performed above the glass transition temperature, it increases the crystallinity of the PVA film, thereby enhancing its mechanical strength and water resistance.

- Freeze-thaw cycling: Crystal nuclei are formed at low temperatures, and thawing promotes crystal growth. The resulting microcrystals serve as physical crosslinking points for the polymer chains, significantly improving the film's mechanical strength and water resistance. After multiple cycles, the tensile strength of PVA film can reach as high as 250 MPa.

3. Synergistic Modification: Towards a High-Performance Future

A single modification method often fails to fully meet the complex performance requirements of PVA film in practical applications. It's tough to boost both strength and toughness at the same time. So, a key approach is to use two nanofillers or methods that work well together. This helps create PVA films that perform well in all areas. For example, combining chemical crosslinking with nanocomposites is currently one of the most promising strategies. Research has shown that synergistic modification of PVA films using succinic acid (SuA) as a crosslinker and bacterial cellulose nanowhiskers (BCNW) as a reinforcing filler significantly improves tensile strength and water resistance, effectively offsetting the shortcomings of single modification methods.

4. Conclusion and Outlook

Remarkable progress has been made in the modification of polyvinyl alcohol (PVA) films. Through the combined application of various strategies, including physical, chemical, and thermal treatments, the mechanical properties, water resistance, and multifunctionality of PVA films have been greatly enhanced. This has significantly promoted the practical application of modified PVA membranes in fields such as water treatment, food packaging, optoelectronic devices, and fuel cells.

Looking forward, research on modified PVA membranes (such as Modified PVA 728F) will focus on the following aspects:

- Synergistic modification: Further exploring the optimal synergistic effect of chemical crosslinking and nanocomposites to resolve the conflict between permeation flux and selectivity of membrane materials and achieve synergistic optimization of multiple properties.

- Functional Expansion: We plan to keep working on PVA films, giving them new features like self-healing and smart responses, so they can be used in more complicated situations.

By building on PVA's natural advantages and using advanced modification processes, polyvinyl alcohol films are likely to become even more widely used in the field of high-performance polymer materials.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

Polyvinyl alcohol (PVA), a water-soluble synthetic polymer, is widely used in textiles, papermaking, construction, coatings, and other fields due to its excellent film-forming, adhesive, emulsifiable, and biodegradable properties. However, standard PVA may have performance limitations (such as water resistance, flexibility, and redispersibility) in certain specific applications. To overcome these challenges, scientists have developed a series of modified PVAs by introducing various functional groups or modifying the polymerization process. Compared to standard PVA, these modified PVA exhibit significant performance advantages in many aspects.

1. Better Water Resistance and Stickiness

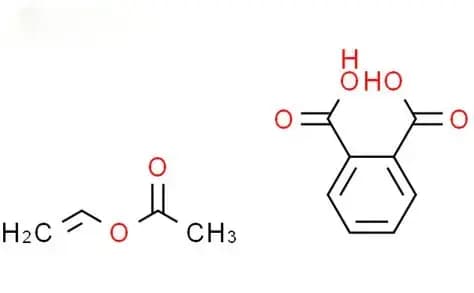

The abundance of hydroxyl groups (-OH) in the standard PVA molecular chain makes it extremely hydrophilic. However, this also means that it is prone to swelling and even dissolution in hot and humid environments, resulting in reduced bond strength. Modified PVA, by introducing hydrophobic functional groups (such as acetyl and siloxane groups) or through crosslinking reactions (such as boric acid crosslinking and aldehyde crosslinking), can effectively reduce its swelling in water, significantly improving its water resistance.

For example, in dry-mix mortars for construction, modified PVA used in tile adhesives can form a more stable and moisture-resistant bond, ensuring that tiles will not fall off due to moisture erosion during long-term use. These modifications also enhance the cohesion between PVA molecular chains, strengthening its adhesion to various substrates (such as cellulose and inorganic powders), thereby imparting higher cohesive and adhesive strength to the final product.

2. Optimized Redispersibility and Compatibility

Certain applications, such as the production of redispersible polymer powders (RDPs), place stringent requirements on the redispersibility of the polymer. Standard PVA, used as a protective colloid, can easily cause emulsion particles to agglomerate during the spray drying process, affecting the final properties of the RDP.

Modified PVA, such as partially alcoholyzed PVA with a high degree of polymerization, produced through specialized polymerization processes, or PVA containing specific hydrophilic/hydrophobic segments, can more effectively stabilize emulsion systems. The protective layer they form after drying allows for rapid and uniform redispersion upon re-addition of water, even after prolonged storage, restoring the original emulsion state. This optimized redispersibility is crucial for ensuring the workability of products such as dry-mix mortar and putty powder.

Furthermore, the introduction of specific functional groups into modified PVA can improve its compatibility with certain additives (such as cellulose ethers and starch ethers), reducing system interactions and flocculation, thereby achieving synergistic effects within the formulation and achieving more stable and efficient product performance.

3. Broader Application Potential and Customizable Performance

While standard PVA has relatively fixed properties, the customizability of modified PVA opens up a wider range of applications. Through precise chemical modification, PVA can be endowed with a variety of customized properties to meet the stringent requirements of specific industries.

For example, silane-modified PVA can significantly improve its adhesion and alkali resistance in cementitious materials; vinyl acetate-modified PVA offers enhanced flexibility and lower film-forming temperatures; and certain bio-modified PVAs may find new applications in the biomedical field. This ability to be "functionalized" to meet specific needs elevates modified PVA from simply a basic raw material to a high-performance additive capable of solving specific technical challenges.

In summary, while standard PVA remains indispensable in many fields, modified PVA, with its significant advantages in water resistance, adhesive strength, redispersibility, and customizability, has achieved a leap from "general purpose" to "specialized," and from "passive" to "intelligent." Whether pushing the performance limits of traditional applications or pioneering cutting-edge technologies such as biomedicine, environmental engineering, and smart materials, modified PVA (such as PVOH 552) demonstrates immense potential and is undoubtedly a key direction for the future development of polymer materials.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

In the ever-changing construction industry, advances in materials science are crucial for promoting project quality, efficiency, and sustainability. From majestic skyscrapers to cozy homes, every structure relies on advanced building materials. Behind these materials lie hidden "unsung heroes" who play crucial roles at the microscopic level, ultimately determining a building's performance and longevity. Vinyl acetate-ethylene copolymer emulsion is one such indispensable and innovative material, its unique properties profoundly influencing the development of modern building materials.

1. What is VAE Emulsion?

VAE emulsion is a polymer dispersion composed of a copolymer of vinyl acetate and ethylene. By varying the ratio of these two monomers, the emulsion's properties can be precisely tailored to meet diverse application requirements.

In the construction industry, VAE emulsion is typically converted into a Re-Dispersible Emulsion (RDP Emulsion). This powder remains stable when dry, making it easy to store and transport. When added to water-based systems (such as cement-based mortars and gypsum-based putties), the VAE powder particles quickly absorb water and disperse, reforming into an emulsion. These redispersed emulsion droplets fuse during water evaporation, forming a continuous, elastic polymer film that firmly binds the inorganic particles (such as cement, gypsum, and fillers) in mortar or putty, providing additional performance enhancements.

| Property | Contribution to Performance |

| Flexibility | Prevents cracking and improves longevity in dynamic applications |

| Adhesion | Forms strong bonds with inorganic materials, enhancing durability |

| Water Resistance | Ensures materials maintain integrity in moisture-prone areas |

| Durability | Enhances overall mechanical properties of construction materials |

2. VAE emulsions give building materials "superpowers"

VAE emulsions (such as Vinnapas 400H) play such a crucial role in building materials due to their unique combination of excellent properties, which are highly compatible with cement-based materials:

2.1 Superior Adhesion

This is one of VAE emulsions' most important contributions. While cement-based materials possess a certain degree of adhesion, they often struggle to adhere firmly to smooth, dense, or porous substrates. VAE emulsions can:

- Form a strong bond: During the drying process, the polymer chains of VAE emulsions penetrate the microscopic pores of the substrate and form a continuous, highly adhesive polymer film on the surface of the cement particles.

- Improved Bonding to Various Substrates: VAE-based materials bond well to a variety of building substrates, including concrete, mortar, gypsum board, wood, metal, and insulation boards, greatly expanding their application range.

- Improved Interfacial Strength: The introduction of VAE significantly enhances the bond strength at the material interface, making the connection between the mortar layer and the substrate, between different mortar layers, or between the mortar and finishing materials such as tiles more secure and reliable.

2.2 Enhanced Flexibility & Crack Resistance

An inherent disadvantage of cement-based materials is their brittleness, which makes them prone to cracking when subjected to stress (such as temperature fluctuations, structural settlement, and vibration). VAE emulsions effectively address this issue:

- Introducing Flexibility: The incorporation of ethylene units into VAE copolymers imparts excellent flexibility to the polymer chains, resulting in a certain degree of ductility after drying and forming a film.

- Absorbing Stress: When the substrate undergoes slight deformation or temperature fluctuations that cause expansion and contraction, the flexible film formed by VAE absorbs and distributes these stresses, preventing the formation and propagation of cracks.

- Improved Impact Resistance: The presence of VAE also makes the material less susceptible to shattering upon impact, significantly enhancing its overall toughness.

2.3 Improved Water Resistance & Durability

The continuous polymer film formed by VAE emulsions significantly improves the material's water resistance and overall durability:

- Waterproof Barrier: VAE films act as an effective waterproof barrier, reducing water penetration, protecting structures from moisture erosion, freeze-thaw cycles, and preventing rusting of internal steel reinforcement.

- Chemical Resistance: VAE polymers generally exhibit good resistance to a wide range of chemicals, enabling the material to maintain stable performance in a wider range of environments.

- Extended Service Life: By enhancing adhesion, crack resistance, and water resistance, VAE significantly extends the service life of building materials and reduces ongoing maintenance costs.

2.4 Excellent Film Formation & Cohesion

The ability of VAE emulsions to form a continuous, uniform polymer film during the drying process is the foundation for the aforementioned properties:

- Particle Fusion: As water evaporates, the polymer particles in the VAE emulsion fuse from their dispersed state through forces such as van der Waals forces and hydrogen bonding, forming a dense, non-porous, continuous film. Improved.

- Cohesive Strength: The VAE film not only bonds to the external substrate but also acts as an internal "adhesive," holding together inorganic particles like cement and sand. This significantly enhances the cohesive strength of mortar or putty, preventing it from flaking or disintegrating.

2.5 Compatibility with Cementitious Systems

VAE emulsions (especially RDP forms) are specifically designed to work synergistically with inorganic binders such as cement and gypsum.

- Excellent Dispersibility: VAE powder quickly and evenly redisperses in water, forming a stable emulsion.

- No Impact on Setting Time: Generally, the addition of VAE does not significantly shorten or prolong the setting time of cement, making construction operations more convenient.

- Synergy: The flexibility, adhesion, and water resistance provided by VAE complement the high strength and hardness of cement-based materials, creating a high-performance composite material.

2. 6 Environmental Benefits

As people become increasingly concerned about health and the environment, the environmental advantages of VAE emulsions are becoming increasingly prominent:

- Low VOC emissions: VAE emulsions and products made from them typically have very low volatile organic compound (VOC) content. This not only helps improve indoor air quality and reduce harm to the human body, but also complies with increasingly stringent environmental regulations.

- Reduced material loss: VAE's improved material performance and durability mean less material loss and a longer lifespan, reducing resource consumption at the source.

3. Typical Applications of VAE Emulsions

Due to these superior properties, VAE emulsions (and their RDP forms) are widely used in:

- Tile Adhesives: Their excellent bond strength ensures tiles remain in place; their excellent flexibility adapts to the thermal expansion and contraction of the substrate and tiles, preventing hollowing and cracking.

- Self-Leveling Compounds: They significantly improve the adhesion, flexibility, and crack resistance of mortars, ensuring a smooth and durable floor screed. Wall Putties/Skim Coats: Improve the adhesion and crack resistance of putty, making it easier to sand and creating a smooth, even wall surface.

- EIFS: Used to bond insulation boards and facing mortar, providing excellent bond strength, impact resistance, and weather resistance.

- Repair Mortars: Strengthen the bond between the repair material and the existing structure, improving the durability and crack resistance of the repair layer.

- Waterproofing Materials: Used in flexible waterproof coatings or mortars, providing excellent waterproofing performance and crack resistance.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

Polyvinyl alcohol (PVA) is a long-used additive in textiles and papermaking. It's great because it makes strong films, sticks well, dissolves in water, and is safe for the environment. However, to meet the increasingly stringent demands of modern industry for material performance, processing efficiency, and environmental responsibility, traditional PVA is being replaced by modified PVA. Modified Polyvinyl Alcohol optimizes its structure and functionality through chemical and/or physical means, enabling it to offer unmatched advantages over traditional PVA in two key industries.

1. Textile Industry: A Performance Leap from Sizing to Printing and Dyeing

In textiles, PVA mainly sizes warp yarns. It coats the yarn with a thin layer before weaving, which makes the yarn stronger and less likely to break. This makes weaving easier and improves the quality of the fabric.

- High-Performance and Efficient Warp Sizing

Enhanced Adhesion and Abrasion Resistance: By introducing hydrophilic or hydrophobic groups and performing graft copolymerization, PVA can enhance its affinity with various fibers (such as polyester, cotton, and blends), resulting in a tougher and more abrasion-resistant sizing film. This means that yarn breakage rates are further reduced on high-speed, high-density looms, significantly improving production efficiency.

Better Sizing and Eco-Friendly Solution: Regular PVA needs high heat and strong alkalinity to remove sizing, which wastes energy and makes dirty water. Modified PVA, with its sizing properties, can be taken off fast with less harsh conditions. This cuts washing time, saves energy, and reduces wastewater treatment, fitting well with green textile plans.

Antistatic and Smooth Properties: Modified PVA can really help with static in yarns. They stop static from building up when the yarn rubs together fast during weaving. This keeps the weaving process running smoothly.

- Diverse Applications in Printing, Dyeing, and Finishing

Modified PVA acts as a thickener in printing pastes. It's also a coating and binder for nonwoven materials. This gives textiles special finishes, improving their feel, water resistance, or flame retardancy.

2. Papermaking Industry: A Core Additive for Improving Quality and Functionality

In the papermaking industry, PVA is primarily used for surface sizing and internal sizing/filler retention, playing a decisive role in the printability, strength, and special properties of paper.

- Surface Sizing: Optimizing Printability and Paper Strength

Excellent Film Formation and Ink Resistance: Using special PVA on paper makes a solid, even layer. This stops ink or coatings from soaking in. The result is clearer printing, shinier paper, and a stronger surface. This is particularly important in the production of high-quality coated paper, inkjet paper, and specialty paper.

Improved Wet/Dry Strength: Adding cross-linking or reactive groups to modified PVA lets it make stronger bonds with pulp fibers. This boosts the paper's strength when it's dry or wet.

- Internal Sizing and Functional Paper Manufacturing

Retention and Drainage Aids: Cationic modified PVA can be used as a retention aid to improve the retention of fine fibers and fillers, saving raw materials and improving paper uniformity.

Specialty Paper: In the manufacture of thermal and pressure-sensitive paper, as well as high-barrier food packaging paper, modified PVA, due to its excellent barrier properties (such as low permeability to oxygen and gases) and good biodegradability, is an irreplaceable choice over other polymer materials.

3. Ongoing Green Commitment

The importance of modified PVA lies not only in its high performance but also in its environmental credentials. PVA's inherent biodegradability and water solubility (depending on the degree of polymerization and modification) make it a "green" alternative to some traditional synthetic polymers (such as acrylics and styrenes). Through precise modification, the industry can achieve higher material recycling rates and a lower environmental footprint while ensuring product performance.

Modified PVA(such as Modified PVA 8048) represents a new era of traditional additives and is a key step in the textile and papermaking industries' transition from "manufacturing" to "smart manufacturing." With increasing demands for sustainable development and product quality, research into functionalizing, compounding, and environmentally friendly PVA modifications is expected to continue in-depth, providing a strong impetus for the future development of these two pillar industries.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

Adhesives are essential for almost every item we use in our daily lives, from furniture and flooring to packaging. Traditional adhesives, such as solvent-based glues and bone glue, have long dominated the market. However, with growing environmental awareness and technological advancements, a new adhesive, VAE Emulsion (Vinyl Acetate–ethylene Copolymer Emulsion), is gradually entering our market.

I. Introduction to VAE Emulsions

Vinyl acetate and ethylene copolymer emulsions typically contain 0-30% vinyl groups. Ethylene acts as an internal plasticizer. A higher vinyl content results in a lower glass transition temperature, a softer resin, and greater flexibility. Ethylene also has low polarity and excellent water resistance. Previously, only polyvinyl acetate emulsions were available, but these had poor water resistance and flexibility, and also exhibited poor adhesion to non-polar or less polar materials such as polyethylene and polyvinyl chloride. VAE emulsions are used in wood glue, paper packaging adhesives, architectural coatings, mortar modification (e.g., waterproofing), and even plastic film lamination.

2. Advantages of VAE Emulsions in Architectural Coatings

- Low VOC

Low-VOC latex paints using VAE emulsions (such as VAE Emulsion CW 40-600) provide a high-quality interior environment with excellent workability and good color development. In Europe, over 90% of zero-/low-VOC interior wall paints use VAE emulsions.

VAE emulsions are the primary binder used in cigarette adhesives.

Compared to acrylic emulsions, vinyl acetate emulsions contain fewer benzenes and aromatic hydrocarbons. Furthermore, they do not require the addition of coalescing agents. Acrylic emulsions, on the other hand, lack the ability to achieve both film-forming and scrub resistance, necessitating the addition of coalescing agents to ensure a high Tg. Vinyl acetate, on the other hand, is softened by water, eliminating the need for coalescing agents.

- Weatherability

The presence of vinyl monomers in VAE emulsions increases the polymer's hydrophobicity, resulting in excellent water resistance in the resulting coating. This is crucial for outdoor coatings, as it prevents rain from eroding the coating, leading to blistering, cracking, and flaking.

Chalking Resistance: Chalking is the phenomenon of paint decomposing due to aging under the influence of ultraviolet light and oxygen, resulting in the formation of white powder on the surface. VAE emulsions have excellent chalking resistance, which helps the coating maintain its appearance and protective properties over time.

Flexibility and Crack Resistance: VAE emulsion coatings exhibit excellent flexibility, adapting to the expansion and contraction of the substrate due to temperature fluctuations. This effectively prevents cracking caused by stress concentration in the coating, thereby extending the coating's service life.

Adhesion: VAE emulsions (such as VAE Emulsion CW 40-602) exhibit excellent adhesion to a variety of substrates, including common building materials such as cement and bricks. Even in adverse weather conditions, the coating remains firmly attached to the wall and resists peeling.

- Cost Advantages

First, there is no need to purchase expensive solvents, reducing raw material costs. Second, its high solids content means that less material is required for the same bonding effect. More importantly, it reduces environmental remediation costs associated with hazardous emissions and potential safety risks. For businesses, choosing VAE emulsions is not only a positive response to environmental regulations but also a long-term, sustainable economic investment.

- Strong Adhesion

Used in Mortar Mixing: VAE emulsion, when added to mortar, increases strength, improves adhesion to various substrates, enhances wear and impact resistance, improves water absorption and permeability, and improves chemical resistance. This polymer mortar is currently widely used due to its excellent properties.

Characteristics of Mortar Mixed with VAE Emulsion:

When VAE is added to mortar, many properties are improved, as shown in Figure 1. However, the performance of the mortar varies depending on the amount of emulsion added. According to Sumitomo Corporation's research, a P/C (polymer weight/cement weight) ratio of 0.1-0.4 is the optimal ratio for both performance and economics.

Increasing Mortar Strength: The fluidity (flow value) of mortar increases with the amount of emulsion added. This fact demonstrates that by adding emulsion, the amount of water can be reduced, resulting in a denser hardened material, increased strength, and reduced shrinkage and water absorption. Improving Mortar Brittleness: When VAE emulsion is mixed into the mortar, vibration-absorbing polymer particles fill the voids in the cement, improving the mortar's impact resistance.

3. Future Development Trends of VAE Emulsions

- Non-PVA Emulsifier Systems

Using a surfactant system and soap-free polymerization technology eliminates the drawbacks of poor water resistance and large particle size caused by PVA's water resistance.

- Copolymer Systems

Using versatate vinyl carbonate, it leverages its high weathering, water, and alkali resistance.

With the growing global focus on sustainable development and green manufacturing, the environmental and health issues associated with traditional adhesives are facing increasing challenges. As a high-performance, environmentally friendly, and versatile adhesive, VAE emulsions are experiencing rapidly growing market demand. Their applications are not only expanding in traditional wood processing, paper products, and textiles, but are also showing great potential in emerging areas such as automotive interiors, building materials, and battery bonding.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

In the field of thermal interface materials (TIM), long-term reliability is one of the core metrics for evaluating product performance, and the choice of filler directly determines the stable performance of TIM. Among these, aluminum nitride (AlN) filler has become an ideal choice for helping TIM break through reliability bottlenecks, thanks to its outstanding characteristics.

The most prominent advantage of AlN filler lies in its excellent resistance to high-temperature oxidation. During the long-term operation of electronic equipment, TIM often faces the dual challenges of thermal cycling and high-temperature environments. Ordinary fillers are prone to oxidative aging, leading to a degradation in thermal performance. In contrast, aluminum nitride can build a "protective barrier" for the TIM matrix, effectively resisting oxidation reactions under high temperatures and slowing down the material's aging process. This ensures that the TIM maintains stable thermal dissipation capability over long-term use, safeguarding the safe operation of electronic components.

Moreover, AlN filler can significantly optimize the physical properties of TIM. Its addition allows for precise adjustment of the TIM's viscosity and cohesion, fundamentally addressing the "pump-out issue" during thermal cycling. It is important to note that the pump-out effect can easily cause TIM to be squeezed out from the interface gap, leading to poor interfacial contact and a sharp decline in thermal efficiency. TIM enhanced with aluminum nitride, due to its stronger cohesion, firmly "locks" into the interface gap. Even after repeated thermal expansion and contraction, it maintains good interfacial contact, ensuring the long-term effectiveness of thermal dissipation.

About Xiamen Juci Technology Co., Ltd.

Xiamen Juci Technology Co., Ltd. is a high-tech enterprise specializing in high-performance aluminum nitride ceramic materials. We are committed to providing cutting-edge thermal management solutions for the electronics industry, with high-thermal-conductivity aluminum nitride filler powder being one of our flagship products.It is widely used in applications such as high-end chip packaging, 5G communication, new energy vehicles, and power semiconductors.

Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com

Fillers are key components in thermal interface materials (TIMs), enhancing their thermal conductivity, mechanical properties, and stability. Typically, fillers are solid particles dispersed within a polymer or grease matrix, serving to improve heat transfer efficiency.

The Roles of Fillers in Thermal Interface Materials:

Enhancing Thermal Conductivity

The base polymer or grease itself has very low thermal conductivity, typically in the range of 0.1–0.3 W/m·K, which is insufficient for the heat dissipation requirements of high-power electronic devices. The addition of fillers is the primary method for enhancing the thermal conductivity of TIMs. For instance, aluminum nitride (AlN) filler, due to its inherently very high intrinsic thermal conductivity (theoretical value can reach up to 320 W/m·K), can significantly improve the overall thermal performance of the composite material, enabling it to reach 10 W/m·K or even higher. This facilitates efficient heat transfer from the heat source to the heat sink.

About Xiamen Juci Technology Co., LTD

Xiamen Juci Technology Co., Ltd. is a leading producer and supplier of high-performance aluminum nitride (AlN) filler. Our company is based on independent research and development and large-scale production, aiming to provide customers with high-quality aluminum nitride powder. Juci Technology is committed to becoming your strategic partner in enhancing thermal management efficiency and product reliability with stable and reliable products.

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com

In modern electronic devices, Thermal Interface Materials (TIMs) play a crucial role. They not only need to transfer heat efficiently but also must possess sufficient mechanical strength to meet the challenges of real-world applications. Whether used as thermal pads or thermal adhesives, issues like material deformation, cracking, or fatigue failure during long-term use can directly impact product reliability.

To optimize these mechanical properties, the industry often incorporates high-performance fillers into the polymer matrix. Among them, Aluminum Nitride (AlN) stands out as a prominent thermal filler, offering benefits that go far beyond enhancing thermal conductivity.

When Aluminum Nitride particles are added to matrices such as silicone grease or silicone gel, The AlN particles reinforce the polymer matrix, preventing excessive deformation under assembly pressure, as well as cracking or fatigue failure during long-term use.

By precisely controlling the amount of aluminum nitride filler, engineers can finely "adjust" the hardness and modulus of the final composite material. This means the material maintains the necessary flexibility for optimal interface contact while also gaining excellent shape retention capability, thereby forming a stable and reliable interface layer. This not only makes the TIM easier to apply during installation but also ensures its long-term stability throughout the device's operational life.

About Xiamen Juci Technology Co., LTD

Xiamen Juci Technology Co., Ltd. is a leading producer and supplier of high-performance aluminum nitride (AlN) filler. Our company is based on independent research and development and large-scale production, aiming to provide customers with high-quality aluminum nitride powder. Juci Technology is committed to becoming your strategic partner in enhancing thermal management efficiency and product reliability with stable and reliable products.

Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com

Under the trend of miniaturization and high-powerization of electronic devices, heat dissipation has become a key bottleneck for performance improvement. The core to solving this problem lies in reducing thermal resistance. Aluminum nitride excels in reducing thermal resistance, mainly due to its high thermal conductivity and ideal particle morphology. It can not only be efficiently integrated into polymer matrices to create unobstructed heat flow channels but also significantly enhance heat dissipation efficiency in applications such as LED packaging, power modules, and 5G base stations.

For enterprises pursuing reliability and performance upgrades, choosing aluminum nitride fillers is not only an efficient thermal conduction solution but also an important means to ensure the stable operation and extended lifespan of electronic devices. In today's increasingly urgent need for heat dissipation, aluminum nitride is becoming the preferred material in more and more industries, opening a new chapter in efficient thermal conduction.

About Xiamen Juci Technology Co., LTD

Xiamen Juci Technology is a leading manufacturer of aluminum nitride powder, aluminum nitride granule, aluminum nitride filler and aluminum nitride ceramics in China. Xiamen Juci Technology is dedicated to the production of aluminum nitride and leads the country in both quality and output. By cooperating with us, we will provide you with efficient thermal management solutions to boost your business.

Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com

When you pick up your phone, take apart an auto part, or look at a home appliance casing, you might not realize that hidden inside these seemingly ordinary plastic products lies a kind of “invisible rebar” — glass fiber (GF). From PP + 20% GF to PA + 60% GF, these reinforcing fibers quietly support the plastic matrix, much like steel bars inside concrete.

Today, let’s uncover the mystery of long glass fibers, short glass fibers, and flat glass fibers, and see how they transform plastics into materials that achieve the perfect balance of strength and flexibility.

Glass Fiber: The “Reinforcement Code” of Plastics

What makes glass fiber the “golden partner” of engineering plastics lies in the fiber–resin synergy, which compensates for the inherent weaknesses of pure plastics:

1. Mechanical Reinforcement: Like adding a hidden skeleton to plastics, tensile strength can be improved by 20%–100%, while impact toughness can even approach the level of metals.

| Material |

Tensile Strength

|

Testing Standard

|

| Neat PP Resin | 30 MPa |

ASTM D-638

|

|

PP Short Glass Fiber Reinforced |

90 MPa |

ASTM D-638

|

| PP Long Glass Fiber Reinforced | 150 MPa |

ASTM D-638

|

The material data varies across different brands.

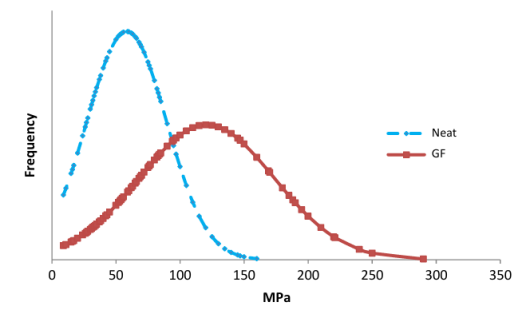

This chart compares the strength distribution of neat polymer (blue dashed line) and glass fiber reinforced polymer (red line). The neat polymer shows lower strength values concentrated around 70–90 MPa, while the glass fiber reinforced polymer exhibits a broader distribution with much higher strengths, extending up to around 300 MPa. This indicates that glass fiber reinforcement significantly improves the material’s mechanical performance.

2. Deformation resistance: suppresses resin shrinkage, making products less prone to warping under high temperature and stress, with a shrinkage rate controllable to as low as 0.15%.

3. Cost balancing: compared with pure engineering plastics, fiber-reinforced materials can achieve high performance at lower cost. For example, using long glass fiber PA to replace metal in automotive parts reduces weight by 58% while cutting costs by 30%. However, different forms of glass fiber bring very different “buffs” to plastics. The right choice can double product performance, while the wrong one may lead to issues such as fiber exposure and brittleness.

Type of fiber: long, short, or flat

The most commonly used glass fibers are long glass fiber, short glass fiber, and flat glass fiber. They differ significantly in morphology, performance, processing methods, and application scenarios, which is also reflected in their structural characteristics:

Glass Fiber Comparison Table

| Type | Length Range | Morphological Characteristics | Core Advantages |

|---|---|---|---|

| Long Glass Fiber | 5–25 mm (commonly 6–12 mm) | Continuous filaments, high integrity | Strength champion, excellent fatigue resistance |

| Short Glass Fiber | 0.1–1 mm (commonly 0.2–0.5 mm) | Short cut segments, easy to disperse | Processing-friendly, balanced performance |

| Flat Glass Fiber | 0.5–5 mm (customizable) | Flat ribbon-like, large surface area | Smooth surface, warp-resistant expert |

Long glass fibers are like “continuous steel bars,” forming a continuous network within the resin and efficiently transmitting stress, which is why their impact strength is 50%–100% higher than that of short glass fibers. Short glass fibers resemble “broken steel slag”: they are evenly dispersed but limited in length, making them suitable for applications that require high isotropy. Flat glass fibers are like “thin steel sheets,” with a thickness of 3–10 μm and a width of 50–200 μm, giving them 3–5 times more contact area with the resin than round glass fibers, directly enhancing surface smoothness by one grade.

Performance Showdown: Who’s Your “Ideal Type”?

When choosing glass fibers, focus on the following key performance dimensions:

1. Appearance

Flake Glass Fiber-Filled PC:

Thanks to its flat ribbon-like structure, the contact area with the PC resin is 3–5 times larger than that of the same weight of round glass fibers. This creates a smoother fiber-resin interface. Combined with a special drawing process that reduces surface roughness, the surface gloss of the molded part (measured at a 60° angle) can reach 80–90, close to a mirror-like finish of pure PC, with almost no visible fiber float.

Short Glass Fiber-Filled PC:

Short fibers are evenly dispersed, causing only mild light scattering. However, the round fiber cross-section still produces minor reflections at the fiber-resin interface. Surface gloss is slightly lower than flake glass fiber, usually around 70–80. Fiber float visibility requires stricter control of the molding process.

Long Glass Fiber-Filled PC:

Long fibers (6–12 mm) tend to form local agglomerations during processing. Due to the “skeleton effect,” tiny gaps exist at the fiber-resin interface, causing diffuse reflection of light in these areas. Surface gloss is only 50–60, resulting in a slightly matte finish. This type is more suitable for functional parts such as engineering machinery housings, where performance is prioritized over appearance.

2. Inner Strength: Mechanical Performance Study

Long Glass Fiber is undoubtedly the “strength champion.” Data shows that at the same content, PA reinforced with long glass fibers has 20–30% higher tensile strength than short glass fiber composites, and notch impact strength is 50–60% higher, making it especially suitable for long-term load-bearing components such as automotive bumpers and wind turbine blades. LFT-G’s Verton long glass fiber composites can even maintain impact strength at -40°C, a performance level difficult for short glass fibers to achieve.

Short Glass Fiber excels in “balance.” Although its strength is slightly lower, it offers good isotropy, meaning the part’s performance is uniform in all directions. This makes it ideal for precision components such as gears and connectors.

Flake (Flat) Glass Fiber improves lateral toughness slightly. For example, using flake glass fiber to reinforce Si-PC blends for smartphone housings can increase drop resistance by 40% while avoiding defects such as fiber protrusion.

3. Dimensional Stability: The Key to Warpage Control

Long Glass Fiber: Its “skeleton effect” firmly restrains the resin, reducing shrinkage along the flow direction to as low as 0.15%. However, shrinkage differences in the perpendicular direction can be significant, making large flat panels prone to warping.

Short Glass Fiber: Shrinkage is more uniform, making it suitable for small to medium-sized parts.

Flake (Flat) Glass Fiber: Thanks to its flat structure, it provides more balanced control over in-plane shrinkage, making it an ideal choice for automotive interior panels.

4. Processing Difficulty

Long Fibers: They tend to tangle, requiring high-performance injection molding equipment. Molds need large runners and gates (≥3 mm), and complex parts may require low-pressure processes such as Injection Compression Molding (ICM), Structural Foam Molding (SFM), or Gas-Assisted Injection Molding (GAIM). Otherwise, fiber breakage can drastically reduce performance.

Short Glass Fiber and Flake (Flat) Glass Fiber: These are easier to process with mature, established methods. They can be molded on standard injection machines, and high-flow grades can even fill thin walls down to 0.5 mm. Flake glass fiber, thanks to its good surface appearance, can achieve better aesthetics than short glass fiber without the need for higher mold temperatures.

Application Scenarios: Putting the Right Glass Fiber in the Right Place

There is no “best” glass fiber, only the most suitable choice. Let’s look at the main arenas for different types of glass fibers:

Long Glass Fiber: The “heavy-duty champion” of industrial applications.

Components such as automotive chassis brackets, engineering machinery housings, and ski binding fixtures that must withstand long-term impacts and loads are best served by long glass fibers. Long glass fiber composites used in cable brackets can last 10 years underground without corrosion, completely solving the rust problems of metal brackets. Long glass fiber-reinforced plastics are also ideal for automotive pedals.

Short Glass Fiber: The “cost-performance king” of consumer goods.

Parts such as washing machine drums, air conditioner compressor brackets, and electronic connectors require basic strength but are cost-sensitive. Short glass fiber-reinforced materials are perfect for these, for example, 30% short glass fiber PA66 gears, which are wear-resistant yet affordable.

Flake (Flat) Glass Fiber: Combines appearance and strength.

Components like smartphone housings, laptop A-side panels, and automotive interior panels need both drop resistance and aesthetics. Flake glass fiber provides a mirror-smooth surface while maintaining sufficient strength even in thin walls of 0.8 mm.

- Bismaleimide Series2

- Cross-Linking agent / Vulcanizing Agent1

- Curing Agent1

- Engineering Plastic Pellets4

- Epoxy Resin2

- Ethylene-VinylAlcohol Copolymer(EVOH)1

- Fish Oil1

- Food Additives3

- Glucosamine1

- Heat-resistant modifier series1

- High Assay Quaternary Ammonium Compounds9

- Low Assay Quaternary Ammonium Compounds13

- Modified Polyvinyl Alcohol1

- Monomalemide Series2

- Other Surfactants/Catalysts8

- Plastic Random Packing1

- Plastic Structured Packing1

- Polyacrylamide1

- Polyurethane Resin2

- Polyvinyl Alcohol (PVA)2

- Power Coatings3

- Quaternary Ammonium Hydroxide4

- Special Quaternary Ammonium Compounds7

- TPU4

- Tertiary Amines1

- UV Ink1

- VAE Emulsion (Vinyl Acetate–ethylene Copolymer Emulsion)1

- aluminum paste1

- antiform2

- fire sleeve2

- resin2